الحار منتجات

ملكنا الإخبارية

maintenance of coal milling plants

Quality Assured Maintenance Management For Coal Handling

Maintenance is the coordinated integration of the operations, maintenance, engineering support, training, and administrative areas of any process in order to increase the efficiency, reliability, and safety of the process. Coal handling plant should be divided into five sections for QAMM. °

获取价格

Operation and Maintenance of Coal Handling System in Thermal

2011/1/1 2. Operation and Maintenance of Coal Handling System Coal handling system in thermal power plant, usually means the technique procedure that coal from loading and

获取价格

Operation Maintenance of Coal Mills Feeders National

Description of different types of Mills Milling system components such as Raw Coal Feeders, Classifiers and variators etc. their design, construction and selection aspects. ... Routine

获取价格

Coal Mill - an overview ScienceDirect Topics

A simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003).In this model the coal

获取价格

Reliability centered early warning strategy for maintenance of

Abstract: In view of the frequent failure of coal mill due to the variable coal quality of power plant, the failure mode and influence of the system components of a medium speed coal mill in a

获取价格

Coal Mill Safety: A Critical Aspect of Power Plant Operations Coal ...

Proper Ventilation: Ensuring adequate ventilation in the coal mill area helps disperse coal dust and reduce the risk of ignition. Ventilation systems must be designed to handle the specific

获取价格

Operation and Maintenance of Coal Handling System

2011/12/31 Then, the safe operation of coal handling system and the proper method of the equipment maintenance are summed up. Belt Conveyor. . Dual drums head actuations Fig.3. Head and tail actuations 1 ...

获取价格

An integrated maintenance strategy for the Babcock 10E Coal Mill

1998/7/1 @misc{etde_630866, title = {An integrated maintenance strategy for the Babcock 10E Coal Mill} author = {MacIntyre, J, Stansfield, D, Allot, P, and Harris, M} abstractNote =

获取价格

Mining Equipment: A-Z List for Maintenance Contractors

2022/2/15 A type of mining equipment used in underground mines to remove large, rectangular sections of coal. Mill. A plant in which mined ore is treated and metals are recovered or prepared for smelting. The term mill can

获取价格

EnFloTech - Milling Plant Solutions: Leading Coal Biomass

EnFloTech is the industry leader in coal and biomass milling plant solutions, providing a full value chain that encompasses design, manufacturing, and installation. ... The company’s dynamic

获取价格

Coal mill pulverizer in thermal power plants PPT

2012/11/17 20. 13.1.Fineness Fineness is an indicator of the quality of the pulverizer action. Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50,

获取价格

ATOX® Coal Mill - Cement

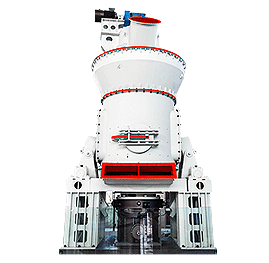

Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal. The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal,

获取价格

Uncovering Insights in Coal Mill Plant Operation Modes Using

The digital transformation of industrial processes offers new possibilities for improving plant performance and reliability. Machine learning and deep learning algorithms have been applied to monitor plant health and develop better maintenance and testing strategies. This paper focuses on the application of these techniques to a coal-fired power plant in South Africa, where coal

获取价格

Mining Equipment: A-Z List for Maintenance Contractors

2022/2/15 A type of mining equipment used in underground mines to remove large, rectangular sections of coal. Mill. A plant in which mined ore is treated and metals are recovered or prepared for smelting. The term mill can also mean a revolving drum used for the grinding of ores in preparation for treatment e.g., ball mill. Off-Highway Truck

获取价格

Operation and Maintenance of Coal-Fired Thermal Power Plants

2024/1/11 This training program is designed to provide participants with in-depth knowledge and skills needed for the efficient operation and maintenance of coal-fired thermal power plants. It's ideal for engineers, technicians, and maintenance personnel in the power generation industry. Module 1: Introduction to Coal-Fired Thermal Power Plants Overview of

获取价格

Mill Inerting and Pulverizer/Mill Explosion Mitigation

Some plants have operated safely with and without these systems. • Coal characteristics profoundly influence risk. – Lower rank coals are generally more easily ignited inside the coal mill. – High volatile matter and highly reactive coals encourage pre-ignition inside the mill.

获取价格

Babcock wins coal milling maintenance contract - crown.co

2021/5/14 The mill operates 24-hours a day and is responsible for the grinding, drying, transporting and classification of the coal. Babcock’s mill maintenance specialist says that the reliability of the mill is essential to ensure correct coal fineness, dryness and throughput, with the performance of the milling plant significantly impacting on plant ...

获取价格

maintenance of coal milling plants - ocea-routage

Coal milling plant maintenance xsm excellent mining crushing machinery products or production line design, the company is committed to coal mills for power plants.Maintenance of coal milling plants.Maintenance manual of coal pulverizer pdf - xiplin coal pulveriser maintenance performance, injection may be costly and may complicate the. ...

获取价格

A Study on 500 MW Coal Fired Boiler Unit’s Bowl Mill

grinding roll wear depth, preventive maintenance data etc., from the plant, are collected. The service checks, overhaul and necessary checks of the operating conditions of certain important components of the mill listed below are undertaken, to ensure the Figure 2. Section of coal bowl mill. Table 1. Guaranteed coal conditions for mill

获取价格

Milling Plant Solutions

Milling Plant Solutions Ltd is a company employing Power Station Engineers specialising in the design and manufacture of mill upgrade packages, aimed at providing mill performance improvement with associated maintenance benefits. Currently, over 200 man years experience as Milling Plant end users and maintainers exist within the company.

获取价格

Predictive Maintenance of Coal Pulverizing Mill Using

One year data was collected for a coal pulverizing mill from a thermal power plant. Output of the coal pulverizing mill was measured for every failure mode and based on the measured output output ...

获取价格

Construction and Maintenance of Belt Conveyors for Coal

6 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants practicalmaintenance also oscillating horizontally. This phenomenon results in internal agitation to the material on belt and therefore the material’s external faces assume inclination at surcharge angle.

获取价格

An integrated maintenance strategy for the Babcock 10E Coal Mill

1998/3/30 Coal-fired power stations around the world have many common features, including similar types of auxiliary plant. One example of such a common area is the coal milling plant. This plant is involved in an inherently wearing process, since the raw coal is an abrasive substance, and the environment is both hostile and demanding. Availability of milling plant is

获取价格

Reliability centered early warning strategy for maintenance of

Abstract: In view of the frequent failure of coal mill due to the variable coal quality of power plant, the failure mode and influence of the system components of a medium speed coal mill in a power plant were analyzed by combining the multi-state estimation algorithm, and a reliability oriented maintenance early warning strategy was proposed. By selecting the key parameters

获取价格

Predictive Maintenance of Coal Pulverizing Mill Using

One year data was collected for a coal pulverizing mill from a thermal power plant. Output of the coal pulverizing mill was measured for every failure mode and based on the measured output output ...

获取价格

Construction and Maintenance of Belt Conveyors for Coal

6 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants practicalmaintenance also oscillating horizontally. This phenomenon results in internal agitation to the material on belt and therefore the material’s external faces assume inclination at surcharge angle.

获取价格

An integrated maintenance strategy for the Babcock 10E Coal Mill

1998/3/30 Coal-fired power stations around the world have many common features, including similar types of auxiliary plant. One example of such a common area is the coal milling plant. This plant is involved in an inherently wearing process, since the raw coal is an abrasive substance, and the environment is both hostile and demanding. Availability of milling plant is

获取价格

Reliability centered early warning strategy for maintenance of

Abstract: In view of the frequent failure of coal mill due to the variable coal quality of power plant, the failure mode and influence of the system components of a medium speed coal mill in a power plant were analyzed by combining the multi-state estimation algorithm, and a reliability oriented maintenance early warning strategy was proposed. By selecting the key parameters

获取价格

Performance optimisation of vertical spindle coal pulverisers

spindle coal pulverising mill’s performance to facilitate optimal plant performance. Plant design and mill’s acceptance test data was analysed to understand the design and subsequent changes over the years of the mill’s operation. The mill outputs, pulverised coal fineness and

获取价格

How Does a Vertical Coal Mill Work - Coal Grinding Mill In Cement Plant

2024/3/16 Ultimately, the finely pulverized coal is transported via a burner pipe to the furnace of a power plant or cement kiln, where it undergoes combustion to generate heat for electricity production or industrial processes, completing the operational cycle of the coal mill. The coal grinding mill serves as a versatile grinding machine, adept at ...

获取价格

Mill maintenance contract at power station awarded - Energize

2021/5/12 Mills Maintenance Specialist for Babcock, Simon Mathe, says that the reliability of the mill is essential to ensure correct coal fineness, dryness and throughput, with the performance of the milling plant significantly impacting plant efficiency. “The milling plant is an integral part of the power station and consists of many dynamic parts ...

获取价格

Detection of Malfunctions and Abnormal Working Conditions of a Coal Mill

2018/5/2 Coal mill malfunctions are some of the most common causes of failing to keep the power plant crucial operating parameters or even unplanned power plant shutdowns. Therefore, an algorithm has been developed that enable online detection of abnormal conditions and malfunctions of an operating mill. Based on calculated diagnostic signals and defined

获取价格

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

power plants maximum requirements of fuel is a coal. The handling of this fuel is a great job. To handle the fuel, i.e., coal, each power station is equipped with a coal handling plant. Maintenance of Critical Equipments for Coal Handling Plants (CHP) of Thermal Power Stations is typical job. The failures of these equipments have led to high ...

获取价格

Pulverizer Maintenance Guide, Volume 1 Raymond Bowl Mills

The pulverizer mill is a critical component in the coal-fired power plant. As the age of the mill increases, the maintenance costs required for continued operation also increase. With the addition of NOx controls, the efficiency of the unit is affected to a greater degree by the air quantity and fineness of the coal going to the furnace.

获取价格

An integrated maintenance strategy for the Babcock 10E Coal Mill

1998/7/1 @misc{etde_630866, title = {An integrated maintenance strategy for the Babcock 10E Coal Mill} author = {MacIntyre, J, Stansfield, D, Allot, P, and Harris, M} abstractNote = {Coal-fired power station around the world have many common features, including similar types of auxiliary plant. One example of such a common area is the coal milling plant. This paper

获取价格

Coal Grinding - Cement Plant Optimization

Mill Feeders: Feeders for coal mill are generally installed directly under hoppers with rod gate in between. The feeders are generally 2 to 3 m long and discharge on to conveyor or feeding chute to mill. For coal mill feeding, table feeders, belt feeders,

获取价格

Pulverizer Capacity is not simply “tons throughput per hour!”

Maintenance”. It is surprising to us that many plants do not perform mill maintenance and overhauls based on accurate coal fineness and distribution test data. The pulverizers are the “heart” of a pulverized coal fueled power plant and as such, must be set up for maximum effectiveness so that the best furnace performance can be

获取价格

Construction and Maintenance of Belt Conveyors for Coal

6 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants practicalmaintenance also oscillating horizontally. This phenomenon results in internal agitation to the material on belt and therefore the material’s external faces assume inclination at surcharge angle.

获取价格الأسمنت رسوم متحركة

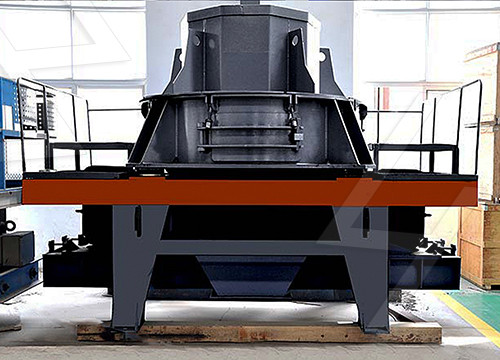

آلة صنع الرمل الاصطناعي vsi الجديدة لعام 2014

النحاس آلة مسحوق فحم

قطع غيار الحجر تزويد mh

مطلوب مصنع مسحوق غسيل الملابس في السعو

100 120 الهيدروكربونات النفطية محطة كسارة الحجر

شنغهاي سحق أسعار المعدات المصنعة

تستخدم الصخور سحق وفرز النباتات بيع

لشراء مصنع كسارة خام النحاس في المملكة المتحدة

موردو معدات تعدين الذهب في ماليزيا

سحق آلة نموذج

إثراء المعادن الهند

المعادن الأباتيت العصابات

مطحنة شارو الكهربائية

كسارة الحجر في لندن للإيجار

سعر آلة تصنيع الرمل في مومباي الهند

سحق الكسارة إلى نشارة الخشب

شركة كسارة مخروطية زا

هارد روك الصخور المحاجر الآلات الهند سحق سعر بيع مصنع

آلة محطم صغيرة الحجم المحلية

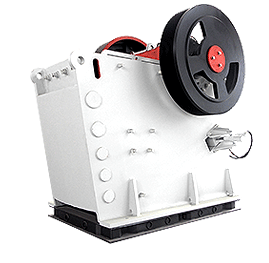

مصنع كسارة الفك في الكويت الكويت

سحق نفايات البناء من النوع المحمول

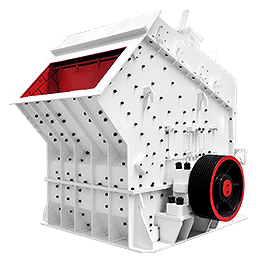

كسارة المطرقة آلة سحق

الشركات التي حجر الكرة مطحنة في أمريكا

أجراس convellor للبيع

سعر كسارة الفحم gundlach 300tph

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20