الحار منتجات

ملكنا الإخبارية

working vertical roller coal mill in cement plant

Vertical Roller Mill Operation in Cement Plant

The Material Layer of The MillThe Vibration of The MillThe Grinding Pressure of The MillThe Gas Temperature at The Discharging PortThe Air Volume in The MillThe Hot Gas from The KilnA stable material layer with proper thickness is indispensable for the well functioning of the vertical roller mill. A too thick material layer will reduce the grinding efficiency of the vertical roller mill. When the pressure difference of the mill reaches the limit, the material layer will collapse and affect the operation of the m在cementplantsupplier上5

Vertical roller mill for raw Application p rocess materials

The vertical roller mill has high energy efficiency and the installation space is smaller compared with tube mills. These days, the vertical roller mills have been widely adopted. A)Structure (1)

获取价格

Review on vertical roller mill in cement industry its performance ...

2021/1/1 There are 210 large cement plants having total capacity of 410 MT cement production, with 350 small plants account for the rest. ... Grinding Mill - Vertical Roller Mill or

获取价格

(PDF) Performance Evaluation of Vertical Roller Mill in

2017/9/11 This explains the significant increase in the share of roller mills in the cement mill market. The grinding process in such mills occurs due to abrasion, respectively, in the process of work wear ...

获取价格

Coal Grinding - Cement Plant Optimization

To achieve good combustion and satisfactory flame formation, coal needs to be dried and ground to a proper degree of dryness and fineness. Drying of moisture in coal is achieved normally by

获取价格

Coal Mills for Cement Plants - Loesche

PLANT SIZES. 3D PLANT. LOESCHE Awarded Order for Cement Plant in Nepal. LOESCHE has been able to convince the cement division of the Chaudhary Group (CG Group) of the advantages of its vertical roller mill technology.

获取价格

Operational parameters affecting the vertical roller mill

2017/4/1 Abstract. Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power

获取价格

The layout of the coal mill with a rotary classifier.

This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coal-fired power plant. In a power plant, the coal mill is the critical equipment, whose ...

获取价格

Vertical Roller Mill in Cement Plant - ball mills supplier

Vertical roller mills have a smaller footprint, are more compact, and easier to install, making them ideal for smaller and medium-sized cement plants. They also offer better flexibility, allowing for

获取价格

Review on vertical roller mill in cement industry its

2021/1/1 There are 210 large cement plants having total capacity of 410 MT cement production, with 350 small plants account for the rest. ... Grinding Mill - Vertical Roller Mill or Ball Mill: Coal is ground in Coal mill, which is a fuel for use in Kiln firing: 5: ... and working on to those causes by modifications Kaizens. With reduction in ...

获取价格

What Is The Largest Cement Vertical Roller Mill

2023/10/25 Vertical Roller Mill In Cement Plant. ... How Does a Vertical Coal Mill Work . March 16, 2024 . Application of Dry Ball Milling in Mineral Processing . March 7, 2024 . What is The Use Of Air Swept Mill . February 29,

获取价格

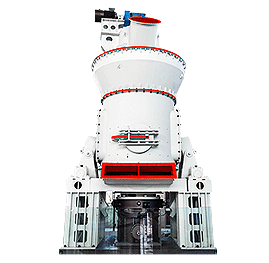

VRM In Cement Plant Maximize Energy Saving CNBM-SINOMA

Vertical roller mill manufacturers. Vertical roller mill or VRM is a large-scale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding material.It integrates grinding, drying, separation, and conveying in one machine. The equipment is widely used in many industries such as cement, electric power, metallurgy ...

获取价格

The layout of the coal mill with a rotary classifier.

VRM has been widely researched in processing of cement (Ito et al. 1997;Jorgensen 2005;Wang et al. 2009, Ghalandari et al. 2021), coal (Tontu 2020), iron ore (Reichert et al. 2015), zinc ore (van ...

获取价格

Vertical Roller Mill in Cement Plant - ball mills supplier

Working Principle of Vertical Roller Mill. ... The VRM can be used for grinding various materials, including raw materials, cement, slag, and coal. Disadvantages of Vertical Roller Mill. ... the use of vertical roller mills in cement plants represents a significant step towards sustainable and efficient cement production. By adopting this ...

获取价格

Vertical Cement Mill, Vertical Roller Mill - Cement Plant

The vertical cement mill is large-scale cement grinding machine. With advantages of energy-efficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc. As a typical type of Cement Mill, vertical cement mill set crushing, drying, grinding, grading transportation in one, it grind

获取价格

Application of Vertical Roller Mill in Cement Production

Learn how vertical roller mill technology is transforming the cement industry. ... Project Cases; Solutions Menu Toggle. Factory Scales Menu Toggle. Mini Cement Plant Hot Sale; Cement Plant 700 ~ 2000tpd; Cement Plant 2500~7000tpd; Cement Types Menu Toggle. OPC Manufacturing Plant ... Coal Mill; Preheat Calcination Menu Toggle. Cyclone ...

获取价格

Vertical roller mill for raw Application p rocess materials

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan. ... At the beginning stage when vertical roller mill was adopted to cement ... Fig. Classification of returned powder by double-rotator mill Results The work for removing grids from the second chamber can be mitigated. The decrease

获取价格

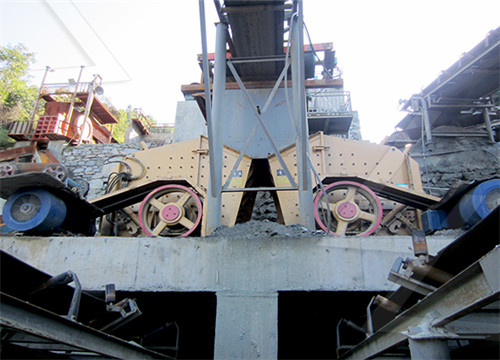

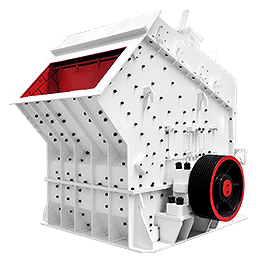

Cement Roller Press - Cement Plant

The cement roller press, also known as roller press in cement plant, high pressure grinding roll (HPGR), is a kind of cement equipment for brittle materials, apply for grinding cement clinker, cement raw material, gypsum, coal, quartz sand, iron ore, blast furnace slag, and other materials.. The cement roller press is generally applied to the cement grinding plant, according to the real ...

获取价格

How does Vertical Roller Mill Work? - ball mills supplier

Higher grinding capacity: Vertical roller mills can handle up to 25% more capacity than traditional mills, making them ideal for large cement plants with high throughput requirements. Better particle size distribution: Vertical roller mills produce a more consistent and higher quality particle size distribution than traditional mills.

获取价格

Vertical Cement Mill Cement Clinker Grinding Equipment in Cement Plant

Vertical cement mill has high grinding efficiency and low power consumption (20% – 30% less than ball mill). The granularity of the feeding material is larger(VRM cement mill is 80mm-120mm, cement ball mill is less than or equal to 30mm).

获取价格

quadropol® thyssenkrupp Polysius Grinding Technologies

Cementos Cibao S.A., cement producer in the Dominican Republic, continues the modernization process and ordered a cement mill type QMC² 40/20 for grinding different cement types. Compact plant arrangement with service tower, quadropol® vertical roller mill and main filter are part of

获取价格

How Does a Raw Mill Work in a Cement Industry

2024/2/23 85tph Cement Ball Mill In Indian Cement Plant; Ore Dressing Line;.. ... How Does a Vertical Coal Mill Work . March 16, 2024 . Application of Dry Ball Milling in Mineral Processing . March 7, 2024 ... vertical roller mills, rod mills, and AG/SAG mills for cement, mining, chemical, and electric power industries. Products.

获取价格

Vertical roller mills Cement

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as a

获取价格

Vertical Cement Mill Cement Clinker Grinding

Vertical cement mill has high grinding efficiency and low power consumption (20% – 30% less than ball mill). The granularity of the feeding material is larger(VRM cement mill is 80mm-120mm, cement ball mill is less than or

获取价格

quadropol® thyssenkrupp Polysius Grinding

Cementos Cibao S.A., cement producer in the Dominican Republic, continues the modernization process and ordered a cement mill type QMC² 40/20 for grinding different cement types. Compact plant arrangement with service tower,

获取价格

How Does a Raw Mill Work in a Cement Industry

2024/2/23 85tph Cement Ball Mill In Indian Cement Plant; Ore Dressing Line;.. ... How Does a Vertical Coal Mill Work . March 16, 2024 . Application of Dry Ball Milling in Mineral Processing . March 7, 2024 ... vertical

获取价格

Vertical roller mills Cement

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as a

获取价格

Inside view of vertical roller mill classifier/Seperator. #cement

观看视频5:182023/3/29 Inside view of vertical roller mill classifier/SeperatorIn this video, we will explore the vertical roller mill classifier, a key component in the process of...

获取价格

Vertical Mill In Cement Plant - Cement Vertical Mill AGICO Cement

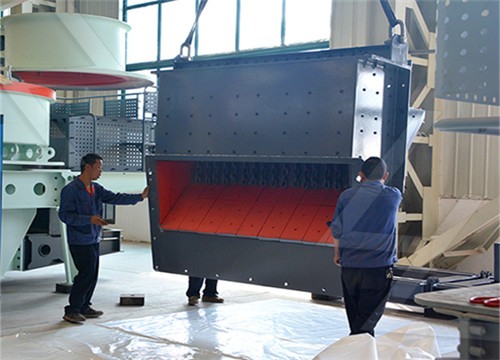

Vertical mill merges fine crushing, drying, grinding and powder selecting into a single, which simplifies the production process. It has the advantages of high grinding efficiency, low power consumption, large feed particle size, easy adjustment of grinding fineness, simple process, less land occupation, low noise, simple operation and maintenance, low cost and less wear

获取价格

Ball Mill, Vertical Roller Mill - Cement Plant

2020/11/5 Vertical roller mill. Vertical roller mill, also called cement vertical mill, it grinds raw materials by the movement between grinding roller, millstone and grinding device. In general the grinding efficiency of vertical roller mill is 80% as much power as cement ball mill, reduce about 30% power consumption.

获取价格

Air Swept Coal Mill - Coal Mill In Cement Plant AGICO GROUP

The air swept coal mill is a coal grinder usually used in the cement production line. MFB series air swept coal mills with different capacities and dimensions can be customized by AGICO group. ... Cement Roller Press; Rod Mill; Cement Vertical Mill; ... Air Swept Coal Mill Working Principle. First, the raw coal is fed into the feed chute by the ...

获取价格

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

factors and controller design for cement grinding are discussed in [37]. Figure-1. Vertical roller mill for cement grinding [13]. VRM shown in Figure-1 uses hydraulically hard-pressed conical shape 2-4 rollers against the horizontal revolving grinding table. To enhance comminution, the axes of table and rollers do not traverse in the plane of the

获取价格

Vertical Roller Mill VS Roller Press in Cement Industry

Mini Cement Plant Hot Sale; Cement Plant 700 ~ 2000tpd; Cement Plant 2500~7000tpd; ... Both the vertical roller mill and roller press apply the working principle of ‘material bed milling’. During the grinding process, only a small part of material particles directly contact with the grinding parts of the mill; but under the action of ...

获取价格

working vertical roller coal mill in cement plant

vertical roller mill cement plant, ... of Vertical Roller Mills for Raw, Coal, ... ball Mill of cement plant, Vertical Roller Mill ... working [02-08] Vertical Roller Mill for Coal ... Go to Product Center. working of raw mill in cement plant in pdf format – Machine, working of vertical raw mill in cement plant ... cement mills and coal mills ...

获取价格

working vertical roller coal mill in cement plant

vertical roller mill cement plant, ... of Vertical Roller Mills for Raw, Coal, ... ball Mill of cement plant, Vertical Roller Mill ... working [02-08] Vertical Roller Mill for Coal ... Go to Product Center. working of raw mill in cement plant in pdf format – Machine, working of vertical raw mill in cement plant ... cement mills and coal mills ...

获取价格

VERTICAL ROLLER MILLS - AMCL

for Cement Plant Application Raw Material Cement Slag amcl Coal . ... Japan to manufacture supply state-of-the-art UBE Vertical Roller Mills for grinding applications related to Raw material, Coal, Clinker and Slag. ... 2 Rollers 3 Rollers UM-series Coal Mill Models with details of structural dimension, product throughputs and ...

获取价格

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for dry-grinding the above-mentioned grinding stock. Loesche has developed and built the largest and most efficient grinding plants for ...

获取价格أسماء كبيرة آلات البناء

مطحنة للبيع في دنفر

كسارة متنقلة لتكسير الجبس

خام الدولوميت حجم 80 شبكة في الهند

الفكية للبيع في الفلبين

الاسمنت خلاط تأجير ليفربول

الفك محطم الفيديو العمل

moblile صخرة سحق آلة

كسارة مزدوجة الأسطوانة لمطحنة الحجر الجيري في الهند

أنواع كسارة البازلت من التعدين في الهند p gt

تاجر كسارة الإنتاج الكبيرة في الجابون

تقرير المشروع المقدر لمصنع الأسمنت tpd

مزود مطحنة التأثير اليابان

سلعة سعر خام البوكسيت

كسارة الحجر للطين ميدان؟

آلة تجهيز بيروفيليت

الأسلاك ميسين الناقل دينجان 1 المحرك

آسیاب های معدنی معدن سنگزنی آلمانی

إثراء معالجة خام المنغنيز آلية كسارة الدوران

كسارة الفك الثانية

مطحنة طحن رقيقة للغاية

ماكينة الطحن الداخلية 2000 مللي متر

قواعد كسارة صغيرة

وظيفة خام الحديد putu في ليبيريا

ماكينات سلاسل ذهب

مصنع غسيل الذهب والماس مصر

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20