الحار منتجات

ملكنا الإخبارية

roller mill for size reduction using compression

Roller mills: Precisely reducing particle size with greater

Ground particles discharged by gravity from bottom roll pair’s roll gap. More about the rolls. Common roll diameters are from 6 to 10 inches, and roll lengths — which vary with the roll

获取价格

Size Reduction – Visual Encyclopedia of Chemical

Size Reduction. Raw materials undergo size reduction through different mechanisms: impact, compression, and attrition. One way to classify size reduction equipment is into crushers and grinders, where grinders produce

获取价格

Analysis of vertical roller mill performance with changes in material ...

2022/5/31 An increase in meta-particle size ratio from 1.1 to 1.2 leads to an 18.7% reduction. The compression force is not large enough when the feed is small, and only part of

获取价格

Mechanochemical and Size Reduction Machines for Biorefining

2020/11/16 In the 1990s, gas compression became less expensive, thus giving an incentive for the industrial use of jet mills. ... Planetary ball mill, 2 min: Size reduction from 0.24

获取价格

(PDF) A Review of Size Reduction techniques Using

2022/6/1 hamme r mills, roller mills and hamme r mills[9]. ... and compression) are used to induce reactions, which occur in a solvent-free environment or with solvents in catalytic amounts (MCRs ...

获取价格

Optimization of working parameters of high-pressure roller mill

4 之 In order to improve the crushing efficiency of high-pressure roller mill and reduce energy consumption, the optimal parameter combination of high-pressure roller mill is sought,

获取价格

Particle Size Reduction with Roller Mill - 911Metallurgist

2019/12/5 The Roller Mill is not suitable for the fine grinding of abrasive materials. The proper fields of application are the reduction of non-metallic minerals, rock products, and

获取价格

A Review on the Technology of Size Reduction

2020/1/1 Examples include hammer mills, roller mills and hammer mills. Crushers can be commonly seen in usage in sugar cane industry where, sugar cane i s subjected to compression force s.

获取价格

A first survey of grinding with high-compression roller mills

1988/4/1 Abstract. The special feature of high-compression roller mills (HC-roller mills) is that a bed of particles is compressed between two rollers to a high solid density more than

获取价格

Size reduction PPT - SlideShare

2019/6/25 For example, in most roller mills compression is the dominant force, impact forces feature strongly in hammer mills and shear forces are dominant in disc attrition 5. ... SIZE REDUCTION EQUIPMENT a) Roller mill

获取价格

Particle Size Reduction with Roller Mill - 911Metallurgist

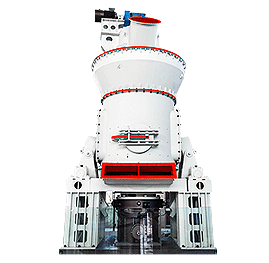

2019/12/5 Raymond Roller Mill Grinding Principle. To a vary large extent the Roller action within these mills reduces particles by compression. Nevertheless there is a certain amount of attrition which is inherent and important. There is also a certain degree of impact. The amount, of compression is provided and controlled mainly by mill speed.

获取价格

DE-11: Lesson 43. SIZE REDUCTION - e-Krishi Shiksha

For example, in most roller mills compression is the dominant force, impact forces feature strongly in hammer mills and shear forces are dominant in disc attrition . ... 43.5 Size-Reduction Equipment a) Roller mill A common type of roller mill consists of two cylindrical steel rolls, mounted on horizontal axes and rotating towards each other. ...

获取价格

A first survey of grinding with high-compression roller mills

1988/4/1 A first survey of grinding with high-compression roller mills. Int. J. Miner. Process., 22: 401-412. The special feature of high-compression roller mills (HC-roller mills) is that a bed of particles is compressed between two rollers to a high solid density more than 70% of volume. The size reduction occurs by interparticle crushing.

获取价格

4. SIZE REDUCTION - cu

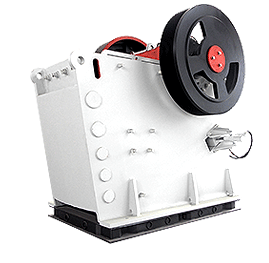

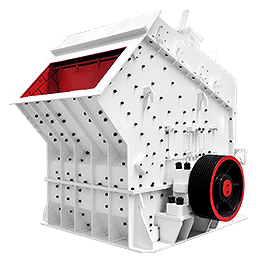

of definite shape and size, typically a few mm in length. The principal types of size reduction machines are: 1- Crushers: a- Jaw crusher b- Impact crushers c- Gyratory crushers d- Crushing rolls 2-Grinders: a- Hammer mills and other impact types b- Ball mills, Tube mills and Rod mills. c- Roller mills and bowl mills d- Attrition mills

获取价格

Size reduction PPT Free Download - SlideShare

2020/8/18 ROLLER MILL:- Method of size reduction: Compression Roller mill consist of two equal size rolls made up of stone or metal with an adjustable gap between them to control the size of the product. Generally one roll is driven mechanically where as the other rotates free. The material to be crushed is dropped from a hopper into the gap.

获取价格

sbm/sbm roller mill for size reduction using pression.md at

Contribute to sbm2023/sbm development by creating an account on GitHub.

获取价格

Industrial Pharmacy Particle-Size Reduction Dr. Mohammad

Roller mills use the principle of attrition to produce size reduction of solids in suspensions, pastes or ointments. Two or three porcelain or metal rolls are mounted horizontally with an adjustable gap, which can be as small as 20 µm. The rollers rotate at different speeds so that the material

获取价格

How to select the right mill for grain particle reduction

2023/2/3 Roller mills. Roller mills accomplish particle reduction by a combination of compression and shearing between two rolls — compression when the rolls rotate at the same speed and shearing when the rolls rotate at differing speeds. Roller mills are typically configured in one, two or three pairs high to provide gradual particle reduction.

获取价格

Size reduction PDF - SlideShare

2019/12/27 The key mechanisms of size reduction are cutting, compression, impact, attrition, and a combination of impact and attrition. Different types of mills use these mechanisms, including hammer mills, ball mills, fluid energy mills, edge runner mills, and end runner mills. ... Ex. Roller mill. 03. Impact = Impact occurs when the materiel is kept ...

获取价格

Roller mill - Lessine

For primary, coarse or medium milling, the roller mill crushes and/or tears the material while keeping strict distribution of particles. ... The roller mill is for coarse or primary reduction of hard, abrasive, or even adhesive materials in the following areas of application: ... Compression springs suited to the product being ground;

获取价格

CHAPTER 3 Size Reduction and Size Separation - Sips

ROLLER MILL Method of size reduction: Compression Construction and working principle: The roller mill has two cylindrical rolls of stone or metal, mounted horizontally, which are capable of rotating on their longitudinal axes. One roll is rotated directly and the other rotates freely. When material is placed above the rolls it is

获取价格

Size Reduction - Pharmaceutical Engineering B. Pharm

2021/10/16 Classification of Size Reduction Equipment’s or Mills 1. CRUSHERS Edge runner mill End runner mill 2. GRINDERS Impact Mill – Hammer mill Rolling compression – Roller mill Attrition mills – Attrition mill Tumbling Mills – Ball mill 3. ULTRAFINE GRINDER Fluid energy mill 4. CUTTING MACHINES Cutter mill

获取价格

Size reduction PPT Free Download - SlideShare

2019/12/5 The mill works on the principle of compression of material by applying a pressure on it. Construction It consists of two cylindrical rollers made of stone or metal, which are mounted horizontally. ... The gap between the rollers can be adjusted to control the degree of size reduction. Uses The roller mill is used for crushing and cracking of ...

获取价格

Roller mill - Lessine

For primary, coarse or medium milling, the roller mill crushes and/or tears the material while keeping strict distribution of particles. ... The roller mill is for coarse or primary reduction of hard, abrasive, or even adhesive materials in the

获取价格

CHAPTER 3 Size Reduction and Size Separation - Sips

ROLLER MILL Method of size reduction: Compression Construction and working principle: The roller mill has two cylindrical rolls of stone or metal, mounted horizontally, which are capable of rotating on their longitudinal axes. One roll is rotated directly and the other rotates freely. When material is placed above the rolls it is

获取价格

Size Reduction - Pharmaceutical Engineering B. Pharm

2021/10/16 Classification of Size Reduction Equipment’s or Mills 1. CRUSHERS Edge runner mill End runner mill 2. GRINDERS Impact Mill – Hammer mill Rolling compression – Roller mill Attrition mills – Attrition mill

获取价格

Size reduction PPT Free Download - SlideShare

2019/12/5 The mill works on the principle of compression of material by applying a pressure on it. Construction It consists of two cylindrical rollers made of stone or metal, which are mounted horizontally. ... The gap between the rollers can be adjusted to control the degree of size reduction. Uses The roller mill is used for crushing and cracking of ...

获取价格

A first survey of grinding with high-compression roller mills

1988/4/1 The special feature of high-compression roller mills (HC-roller mills) is that a bed of particles is compressed between two rollers to a high solid density more than 70% of volume. ... The size distributions of the ground solids were analyzed for energy-size reduction relationships and for development of a model of grinding kinetics in terms of ...

获取价格

Size Reduction Equipment: Principle, Types, Uses Benefits - IQS

Ball mills are one type of size reduction machine. Ball mills, together with impact crushers, grinding mills, and a range of other tools, are utilized for the reduction of all varieties of objects for all varieties of purposes. ... facilitating size reduction through compression. Cone crushers, with their conical shape, crush stones by ...

获取价格

Solids and powder milling - Size reduction - PowderProcess

High compression roller mill: The mills are equipped with 2 rolls turning in opposite direction. The product is fed between the 2 rolls. ... Mills with size reduction media: Ball mills (dry) Ball mills are basically made of a drum partially filled with a grinding

获取价格

Powder Handling: Size Up Size Reduction - Chemical Processing

2017/8/14 A common mill design employs three grinding roll assemblies; these often use tapered roller bearings. Stop bolts support the system and allow adjustment of the clearance between roller and bowl. Compression springs or another compression mechanism mounted above the roller assembly apply pressure for grinding.

获取价格

Mechanism of size reduction.pptx Free Download - SlideShare

2022/8/27 3. Modes of size reduction: Cutting: The material is cut by means of a sharp blades Eg : cutter mill Compression: In this mode material is crushed between roller by the application of pressure Eg : roller mill Impact: This involve the operation of hammer/bars at high speeds. When a lump of material strikes the rotating hammers, the material splits apart.

获取价格

Size Reduction: Introduction, Advantages, disadvantages

2021/3/31 Size reduction is a process of reducing large unit masses into small unit masses like the coarse or fine particles. Size reduction is also known as comminution or diminution or pulverization. ... Cutter mill: 2. compression: ... Roller mill: 3. Impact In this, the substance is subjected to hammers or bars at high speed

获取价格

Size reduction PPT Free Download - SlideShare

2021/6/16 15. Rittnger’s Law States that the energy required for size reduction is proportional to the change in surface area of the pieces of food The power n the value of 2 and following relation, known as kick’s law is obtained: 𝐸 = 𝑐 1 𝑋𝑝 − 1 𝑋𝑓 E is the energy per unit mass required for the production of a new surface by reduction. c is called Rittinger’s constant and

获取价格

Roller Mill For Size Reduction Using Compression

Roller Mill For Size Reduction Using Compression. Roller Mill For Size Reduction Using Pressionmining . A twinroll crusher is selected like those given in the roll crusher capacity table above to serve as the reduction crusher the smallest 24 x 16 roll crusher shown in the roll crusher capacity table above has enough capacity with a setting of ...

获取价格

Comparing The Most Common Types of Mills - ABM Equipment

Universal Mills. Universal mills use interchangeable turbine and pin configurations to provide optimal grinds for the most flexible range of inputs and finished products possible use a rotating pin or rod to grind or crush materials into smaller particles. They are often used to reduce the size of hard or abrasive materials, and can grind a wide variety of materials, including minerals ...

获取价格

Size Reduction: Significance, Mechanisms, Factors, and Differernt ...

2023/7/12 Size Reduction: Significance, Mechanisms, Factors, and Differernt Methods » Pharma Notes Size reduction refers to the process of reducing ... causing it to fracture. Examples of equipment using compression include crushers, roll mills, and tablet presses. ... while a roller mill is used on a larger scale. Impact: Impact occurs when a ...

获取价格وكم تكلفة كسارة الحجر الجيري

أوكرانيا كيلووات كسارة المطرقة

اللوازم الصناعية ماكينات تعدين ومناجم ماكينات تعدين

نقشه صفحه پشتیبانی سنگ شکن مخروطی و جزئیات مربوط به سنگ شکن های FA

قانون محاسبه بنیاد سنگ شکن

احدودب لمدة 4 مرحبا لفة عمل طاحونة

الحديد الهيماتيت خام الحديد فاصل المورد من خنان

فيديو كامل لخط انتاج بدرة الجبص

Buy Belt Conveyor 650

مطحنة سطح عام 12 حصان

كمية هاون الاسمنت في الجص

ABB ballmill العملية

مخطط مصنع كسارة الحجر cme

كسارة مخروطية بينيديا الدولوميت يانغ ديغوناكان

كيف تسحق رمال القطران العلوم في كندا

العمل منجم الميثان منجم الفحم الميثان سم

طحن طحن grindingsale

الطين الكرة مطحنة التعدين

قطع غيار كسارة الفك

كيفية يعمل مطاحن الكرة في ميغاواط النباتات

VSI كسارة SVEDALA

كسارة القارب

عملية تركيز فحص خام الحديد

كسارات مخروطية مستعملة لنا

البحث التعدين المستمر

كسارة خام الحديد المغناطيسية للبيع

حول لدينا

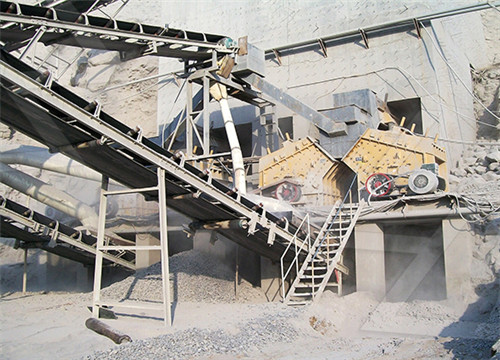

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20