الحار منتجات

ملكنا الإخبارية

corn dry milling process sudan

Dry Milling - an overview ScienceDirect Topics

Dry Milling. In subject area: Agricultural and Biological Sciences. Dry milling is the dry process by which the tip cap, bran, and germ are removed from the corn kernel and the remaining

获取价格

Milling of corn.ppt - SlideShare

2023/4/11 17. Milling of Corn The basis of the maize milling process is the separation of the maize kernel into its different parts. Starch has been produced from corn for many years by two general procedures, namely 1. Dry milling 2.

获取价格

Dry milling and fractionation of grain - Wikipedia

Dry milling of grain is mainly utilized to manufacture feedstock into consumer and industrial based products. This process is widely associated with the development of new bio-based associated by-products. The milling process separates the grain into four distinct physical components: the germ, flour, fine grits, and coarse grits. The separated materials are then reduced into food products utilized for human and animal consumption.

获取价格

Comprehensive utilization of corn starch processing by-products:

2021/9/1 Corn is a high starchy cereal crop with the highest production and provides over 85% of the starch produced worldwide. Various by-products, differentiated by technological

获取价格

The wet and dry milling processes. Download

Download scientific diagram The wet and dry milling processes. from publication: Comprehensive utilization of corn starch processing by-products: A review Corn is a high starchy cereal crop ...

获取价格

Lesson 6. CORN: CLASSIFICATION, DRY MILLING AND WET MILLING

Wet milling and dry milling involving de-germing are carried out in large commercial mills. 6.3.1 Dry milling. Two different systems are used for dry milling of corn. The non-degerming system

获取价格

Corn Dry Milling: Processes, Products, and Applications

2019/1/1 The expansion of the global corn market and corn processing industry by either dry milling or wet milling generates a large amount of by-products, including husks, germ, and

获取价格

Corn Milling: Wet vs. Dry Milling - AMG Engineering

This versatile grain is comprised of four components that make manufacturing of a variety of products possible. Corn’s components are Starch (61%), Corn oil (4 %), Protein (8%) and Fiber (11%) – approximately 16% of the corn kernel’s

获取价格

Corn dry milling process flow diagram. - ResearchGate

The sweet potato was characterized by moisture and total reducing sugars. When the enzymes are added simultaneously, the optimal conditions are 35 °C and 25.1 h for a minimum yield of

获取价格

ISSUE C ETHANOL PRODUCTION FROM CORN DRY MILLING

The process examined is a typical dry milling process. In the process examined, corn is ground, slurried with water and then submitted to enzymatic hydrolysis, which converts starch to ... the report “Ethanol Production from Corn Dry Milling.” The changes in each revision are classified according to the types presented below: * Fix: errors ...

获取价格

Corn Dry Milling: Processes, Products, and Applications

2019/1/1 This new corn dry-milling process incorporates the Satake hydrator for precise tempering control to “precondition” the corn kernels for optimal separation of bran and germ from the endosperm. The tempering step is followed by the Satake maize degerminator, a cylindrical device that is oriented vertically instead of horizontally, as is the ...

获取价格

Dry Milled Corn Market Size, Industry Share Forecast, 2032

The end-products derived by the dry milling process of corn such as ethanol, cornmeal, corn flour and others are used for manufacturing feed, food and biofuel. In current times there has been a surging demand for convenience and ready-to-eat food products has led to increasing in demand for dry milled corn-derived products. The dry milled corn ...

获取价格

Wet milling of corn PPT Free Download - SlideShare

2018/4/25 Wet milling of corn - Download as a PDF or view online for free ... 7 likes • 6,870 views. Faixal Aziz Follow. Wet milling of corn is a process that separates corn into its components like starch, corn oil, protein, and fiber. ... known as light steep water Almost 6 percent of the original dry weight of the grain 35 to 40 percent is protein ...

获取价格

Dry milling and fractionation of grain - Wikipedia

Dry milling of grain is mainly utilized to manufacture feedstock into consumer and industrial based products. This process is widely associated with the development of new bio-based associated by-products. The milling process separates the grain into four distinct physical components: the germ, flour, fine grits, and coarse grits.The separated materials are then reduced into food

获取价格

A new lab scale corn dry milling protocol generating commercial

2017/12/15 The objective was to develop a 100 g lab scale dry milling protocol to determine effects of corn cultivars on coproduct fraction yields and composition.Six yellow dent, three colored and one white cultivar of corn were processed using 100 g samples to generate six coproducts, namely large grits, medium grits, small grits, fines, germ and pericarp.

获取价格

2023 Corn Dry Milling Conference - NAMA

The Corn Dry Milling Conference is co-sponsored by NAMA and the U.S. Department of Agriculture’s National Center for Agricultural Utilization Research (NCAUR) in Peoria, Illinois. Since 1959, this one-day conference has provided a forum for the entire value chain to share the latest research on corn, corn milling, consumer trends, product ...

获取价格

Corn: A complete guide to sourcing, storing, milling, cooking, and ...

2023/8/23 Preparing the Corn. Before milling, it’s essential to prepare the corn properly. It’s important to start with clean and dry corn kernels. I prefer to buy non-GMO organic corn, as it is free of pesticides and other chemicals. For milling corn into masa harina, a specific type of cornmeal used in making tortillas, I follow the nixtamalization ...

获取价格

Corn dry milling process flow diagram. - ResearchGate

Download scientific diagram Corn dry milling process flow diagram. from publication: Bioethanol production: Feedstock and current technologies Fossil fuels such as oil, coal and natural gases ...

获取价格

Isha singh dry milling of corn ppt PPT Free Download

2021/1/22 Dry milling is the simplest method of producing maize products for human consumption. Dry corn millers process corn in one of three ways: (1) Tempering de-germing process (2) Stone-ground or non-degerming process (3) Alkaline-cooked process. The most common process is the “tempering- degerming.” Dry milling of corn

获取价格

Agricor Proud Millers of Dry Milled Corn Products

We are proud millers of Certified Organic, Non-GMO and conventional dry-milled corn products that we sell to food, industrial, companion animal and feed customers worldwide. ... milling and packaging process. Shipping To you. We have local, reliable transportation partners that help us deliver your product to your door when you need it. We ship ...

获取价格

Corn Germ - an overview ScienceDirect Topics

Approximately 10% of the edible corn oil (corn germ oil) in the United States is obtained from corn germ that is produced by a process called dry milling. Corn dry milling was also developed in the 1800s as a process to remove bran and germ from corn to create a corn meal with a longer shelf life (because of the reduced amount of germ that is ...

获取价格

GHG Analysis of Dry Mill for Corn Ethanol Production under

2022/12/1 Corn Ethanol GHG Analysis Dry mill corn ethanol plants process corn and sorghum into ethanol with distillers grains and corn oil as co-products. The majority of U.S. ethanol production are located in the Midwest and Upper Midwest States, where ethanol plants are close to a consistent supply of corn, water,

获取价格

Dry Fractionation Corn Milling Bio-Process Group

The Bio-Process group has been developing the concept of modularly constructed bio-refinery production capacities using front end dry-milling fractionation of the corn. The size of the facilities are dictated by the dry-milling equipment on the front end. Dry fractionation systems are marketed by various vendors.

获取价格

Agricor Proud Millers of Dry Milled Corn Products

We are proud millers of Certified Organic, Non-GMO and conventional dry-milled corn products that we sell to food, industrial, companion animal and feed customers worldwide. ... milling and packaging process. Shipping To you. We have local, reliable transportation partners that help us deliver your product to your door when you need it. We ship ...

获取价格

Corn Germ - an overview ScienceDirect Topics

Approximately 10% of the edible corn oil (corn germ oil) in the United States is obtained from corn germ that is produced by a process called dry milling. Corn dry milling was also developed in the 1800s as a process to remove bran and germ from corn to create a corn meal with a longer shelf life (because of the reduced amount of germ that is ...

获取价格

GHG Analysis of Dry Mill for Corn Ethanol Production under

2022/12/1 Corn Ethanol GHG Analysis Dry mill corn ethanol plants process corn and sorghum into ethanol with distillers grains and corn oil as co-products. The majority of U.S. ethanol production are located in the Midwest and Upper Midwest States, where ethanol plants are close to a consistent supply of corn, water,

获取价格

Dry Fractionation Corn Milling Bio-Process Group

The Bio-Process group has been developing the concept of modularly constructed bio-refinery production capacities using front end dry-milling fractionation of the corn. The size of the facilities are dictated by the dry-milling equipment on the front end. Dry fractionation systems are marketed by various vendors.

获取价格

9.9.7 Corn Wet Milling - U.S. Environmental Protection Agency

In the corn wet milling process, the corn kernel (see Figure 9.9.7-1) is separated into 3 principal parts: (1) the outer skin, called the bran or hull; (2) the germ, containing most of the oil; and (3) the endosperm (gluten and starch). From an average bushel of corn weighing 25 kilograms

获取价格

ABITHA FRANCIS drymilling and wet milling of corn PPT

2020/9/22 •Mainly the milling process of corn are in two types wet milling and dry milling . 3. STRUCTURE AND COMPOSITION OF CORN:- 4. PROCESSING OF CORN:- •Corn is one of the worlds most popular cereal grains . It’s the seed of a plant in the grass family , native to central America but grown in countless varieties world wide. ... • The corn dry ...

获取价格

corn germ oil processing oil extraction machine oil mill in sudan

KMECis always committed to offer professional corn germ oil production process and quality corn germ oil production machines. we are your trustable manufacturer and supplier of oil production in China.. corn germ oil is a commonly used oil that is used by many around the world for their cooking needs. corn germ oil production process is a ...

获取价格

Ethanol Plant Diversification — Cereal Process Technologies Corn ...

CPT is the proven gateway technology that allows companies to make higher value products from commodity and specialty corn. CPT uses a patented dry milling process to separate the kernel’s parts before endosperm, or the fermentable starch, is introduced into the fermenter. And it keeps the non-fermentable germ and bran for new markets and new ...

获取价格

Conceptual process flow diagram for a corn-based, dry-milling

Based on an analysis of the dry milling process, (7) estimated that steam represents approximately 15% of the total production cost (base case) estimated at US$1.61 = gal (0.43 US$ = L), before ...

获取价格

About — Cereal Process Technologies Corn Fractionation

His process and design innovations continue to advance corn dry-milling technologies. CPT's dry corn fractionation technology has been used for more than 3 decades to produce ingredients for the beverage, alcohol and snack foods industries and petroleum drilling fluids, making it the most proven fractionation technology in the industry.

获取价格

Corn Processing Maize Processing - Group

Our production processes make corn flour for tortillas, nachos, arepas, corn flour, instant maize meal and other corn based products. Corn offers a great market opportunity. Every year one billion tons of corn is harvested worldwide. 175 million tons is processed into food, and that figure is rising due to gluten-free foods. +

获取价格

Corn Dry Milling: Processes, Products, and Applications

2019/1/1 Generally, 52% of the total corn produced in the world is used in animal feed, 37% in ethanol production (fuel and beverage), and 11% in food production [70]. In the corn dry milling process, the corn endosperm was ground to obtain corn grits, meals, and flours, while a lot of by-products are obtained, such as corn bran and germ [71].

获取价格

An Enzymatic Process for Corn Wet Milling Request PDF

2004/2/1 Although corn wet milling-based biorefineries require higher initial capital investment and higher processing costs than dry milling systems, the former is the dominant process for large plants ...

获取价格

Dry and wet milling of corn PPT - SlideShare

2014/2/6 9. MILLING AND SEPARATION The corn is coarsely milled in the cracking mills to separate the germ from the rest of the components (including starch, fibre and gluten). The corn flows to the germ separators to separate out the corn germ. The corn germ, which contains about 85% of the corn’s oil, is removed from the slurry and washed. It is then dried and sold

获取价格معايير لتركيب كسارة الحجر على

آلة تصنيف الرمال الحلزونية ذات الكفاءة العالية لخام الذهب وخام الحديد وخام الزنك

سنگ شکن فکی سری پیو با دوام

2pg سلسلة عالية الجودة 400x250 كسارة الأسطوانة

التعدين والمعالجة المعدنية للحديد الذهب

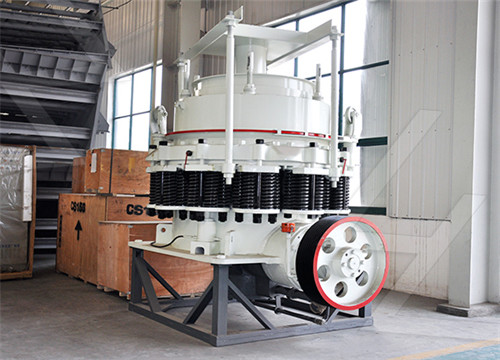

الربيع مخروط محطم ترقيات

طحن التجفيف مصمم

مورد اسمنت تكسير الرمال في مظفر اباد

ماشین سنگ زنی چین

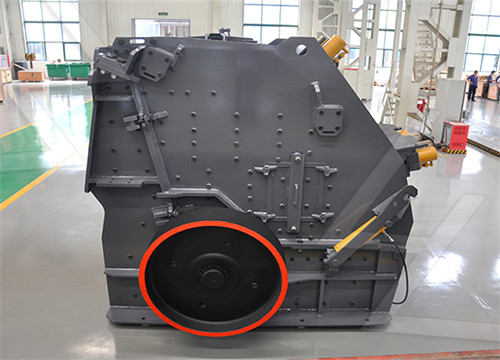

مختلف عمل كسارة الفك الرئيسية

شنغهاي مواد البناء باستخدام طاحونة

مطحنة الصخور للودر

المورد رمل السيليكا في الصين

كسارة مخروطية مستعملة في فرنسا

كسارة صناعة خام الحديد

وحدات تكسير الأحجار في الهند

تستخدم اليابان آلة طحن الحجر

صبخي نبهان صناعة النحاس

معدات التعدين كسارة ايطاليا

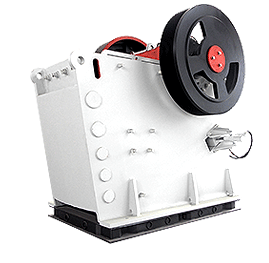

تخطيط الفني لكسارة الفك

600TPH Rock Crusher

آلة كسارة الرخام عالية الكفاءةكسارة مخروطية لخط إنتاج الحجر

شنغهاي تغذية كسارة المتجددة

نشرت كسارة الفك

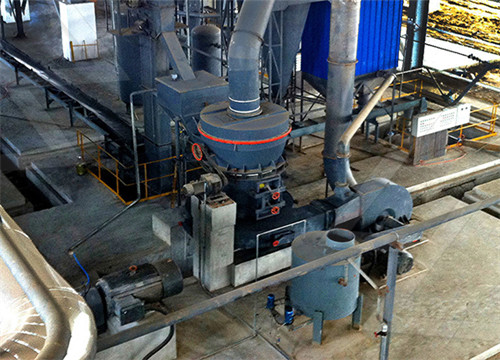

الرأسي مطحنة loesche الصين

عالية السعة خام الجرانيت الحجر الجيري كسارة الفك الصخور pe 250x400

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20