الحار منتجات

ملكنا الإخبارية

removing a broken carbide ball mill from hole

Removing a broken carbide drill - Practical Machinist

2014/7/23 Removing a broken carbide drill. Thread starter MacDaddy Start date Jan 4 ... I used to use a hollow drill to remove the entire drill and screwed up hole, then weld it back up, and redo. M. MacDaddy Plastic. Joined Jul 23, 2014 Location ... small pecks and it will surely ruin

获取价格

Broken carbide end mill in aluminum - Practical Machinist

2011/2/5 So I broke a 1/16" carbide end mill in a part at 10:00 Friday night. ... You can make the dig out hole smaller, get a piece of drill rod, drill a hole up the middle to clear broken

获取价格

how to extract a broke carbide drill bit? - The Home Shop

2004/2/9 My understanding is this is a broken drill bit, a carbide tap drill. Very small, .089" [This message has been edited by Evan (edited 02-10-2004).] ... there was no way to back it

获取价格

How do you remove broken carbide endmill? : r/CNC - Reddit

Sometimes this works: put a used 3mm end mill in spindle, jog to position of the hole and hand jog into the broken endmill VERY slowly, like it could take you 30 mins to get thru the broken

获取价格

CNC Machining Milling out a broken tap - Practical Machinist

2004/2/24 I have had good luck removing a broken HSS tap this way: Start with a 90 degree carbide spotting drill / chamfer tool that is as short as possible and get a spot going on

获取价格

How do I extract a broken drill bit from a deep hole? - CNCzone

2011/9/22 From there, just spin the mill in reverse to back the broken section back out via the protruding drill rod chucked up. Drill rod two sizes down, take one end to a point, the either

获取价格

How to Remove a Broken Drill or Tap (with videos)

观看视频Success rate: 90% with a few broken carbide endmills and mangled threads. EDM. This, in my opinion, is the hands-down most reliable and cleanest way of getting a broken tap or drill out of a hole. I’ve removed hundreds of broken taps this way, and it works pretty well every time.

获取价格

Help! Best way to remove broken .062 carbide drill bit from piece?

Use a carbide end mill to SLOWLY mill through the drill. Use ample coolant. The end mill will likely chip/break once the drill is separated into 2+ pieces. Once the drill is in pieces, grab a

获取价格

Tips and or tricks for removing a broken tap from a blind hole?

Grind a drill tip on them (2 cutting edges. No flutes.). Then into the bridgeport at 1500ish rpm. And burn through the tap. The carbide will last while the high speed steel will melt and turn to small

获取价格

General Removing broken screws - Practical Machinist

2014/8/27 Find an old carbide endmill - It can be dull, broken, doesnt' matter. Put it in your mill, and LEAN on that sucker. See, the thing is, even if it's fubar-broken, the endmill will still

获取价格

Removing a broken tap from a through hole without access to a mill.

Now my current plan is to mount a straight grinder (4500–30000rpm) in a magnetic drill stand and use either a carbide end mill or diamond drilling bit to slowly get it out. I got the grinder and the stand but no end mills or other straight grinder tools. It

获取价格

General How do I remove a tap with a carbide endmill?

2012/1/27 There's a broken 1/2-13 tap in a through hole in a 2" piece of 1018. There's only about an inch of the tap left in the hole, but it's about in the middle, so I can't weld to it, and don't have an EDM to play with. I can get it on the milling machine table, and have a few reground 1/4" and 3/8" center-cutting carbide end mills to invest.

获取价格

How do you remove broken carbide endmill? : r/CNC - Reddit

4mm carbide endmill broken while I was doing circular interpolation (bore in Fusion) the material is Stainless steel 304. ... in case you didn't already figure it out, too much end mill for that size hole. The end mill needs a little bit of breathing room down in that hole. ... FYI there are spindle mountable EDMs you can get that save a lot of ...

获取价格

CNC Machining Pecking out a broken end mill inside of a broken

2015/7/25 Hello, I was charged with the duty to peck out a 1/4-20 tap stuck about .5" deep inside of a casting. Before I could complete the job an associate came in behind me and broke the carbide ball mill off inside of the tap which is still stuck in the hole.

获取价格

Removing a broken form tap, it can be done - Practical Machinist

2013/1/11 So, I used my usual method. I chucked up a 3/32 carbide end mill that was laying around. I hand wheeled it down through the tap .001 at a time running 500 RPM with the hole full of oil. The end mill didn't quite make it to the end of the tap, but it got close enough that I could finish with a 2mm end mill that I had.

获取价格

Broken reverse trip ball lever - Practical Machinist

2012/1/3 I started with a carbide bit in a dremel to grind down any burrs in the hole and the end of the ball. I then took and flipped the mill head so ball was facing down towards the table. I wiggled and jiggled the downfeed depth rod until the ball was as loose as it could be. Next I took a small allen wrench put a drop of hot glue on it and stuck it ...

获取价格

CNC Machining Help milling broken tap - Practical Machinist

2012/9/28 Start with a carbide Ball end mill, then a Carbide spade drill just smaller than the minor D of the broken tap. You do not want to use too large a D bit, the broken teeth of the tap will jam, and guess the results. Keep pecking, and use a punch to break off the teeth as you go deeper, blow out often. Slow work gets the job done quick.

获取价格

Help ! Trying to remove broken tap with carbide ball burr

2011/4/26 Hello I broke a HSS 3/8 BSW tap in aluminium. After reading lots of posts, I purchased a 6mm carbide ball burr. I am holding the burr in my mill ER chuck. This worked great for the first peck but the burr now just makes a bowl shaped depression and won't cut. It looks like the burr won't cut...

获取价格

Removing broken HSS drills : r/Machinists - Reddit

A little update, tried to go down the hole now with a 6mm x20d solid carbide drill. Got all the way to 153mm deep and retracted then shattered 🥲, no idea what’s went wrong. I’m thinking the HSS drill has wandered and made the hole bent so carbide drill

获取价格

drill out broken drill bit use big or small drill - Practical Machinist

2008/12/13 had a .129 hss drill broke about 1.5" deep into cast iron (casting weighs 1 ton). so i start with 1/8 carbide endmill but end up using 3/16 carbide endmill to drill it out . get about .25 deep with each 3/16 endmill til the broke drill pieces

获取价格

2-56 tap broken off in 304SST blind hole - panic job of course

2005/5/28 Its not hard to sharpen a chisel point on the end of an broken end mill, it will cut and make shavings if you feed slow and let the carbide do its job. Drilled out a 1/4-20 just last Wednesday with a 3/16 carbide end mill, I didn't chisel point it, didn't have to, it still had a good center but a chipped flute.

获取价格

How to Remove a Broken Carbide Drill Bit - HandyTooler

2023/4/22 How to Remove a Broken Drill Bit from Aluminum . If you’re working with aluminum and a drill bit breaks, don’t panic. Here’s how to remove a broken drill bit from aluminum: First, use a hammer to gently tap the end of

获取价格

Removing tap, not concerned with the hole : r/Machinists - Reddit

Carbide drill for sure, this my primary reason for saving old carbide. 1000 rpm and steady pressure. You may need to grind a pin punch to a point to pick out some remains. Broken taps/drills used to scare me to death, but with a bit of experience it becomes rather easy to

获取价格

Removing broken thread former - Practical Machinist

2008/12/3 removing broken forming taps Hi hesstool: I've done it successfully, but it can be hit or miss. ... Another option if you have an exact location of the hole is to drill it out with a carbide ball nose end mill. For an M4x.7 tap you can use a 1/8 end mill. Instead of using the quill, use the hand crank and feed the table up slowly. ...

获取价格

2-56 tap broken off in 304SST blind hole - panic job of course

2005/5/28 Its not hard to sharpen a chisel point on the end of an broken end mill, it will cut and make shavings if you feed slow and let the carbide do its job. Drilled out a 1/4-20 just last Wednesday with a 3/16 carbide end mill, I didn't chisel point it, didn't have to, it still had a good center but a chipped flute.

获取价格

How to Remove a Broken Carbide Drill Bit

2023/4/22 How to Remove a Broken Drill Bit from Aluminum . If you’re working with aluminum and a drill bit breaks, don’t panic. Here’s how to remove a broken drill bit from aluminum: First, use a hammer to gently tap the end of the

获取价格

Removing tap, not concerned with the hole : r/Machinists - Reddit

Carbide drill for sure, this my primary reason for saving old carbide. 1000 rpm and steady pressure. You may need to grind a pin punch to a point to pick out some remains. Broken taps/drills used to scare me to death, but with a bit of experience it becomes rather easy to

获取价格

Removing broken thread former - Practical Machinist

2008/12/3 removing broken forming taps Hi hesstool: I've done it successfully, but it can be hit or miss. ... Another option if you have an exact location of the hole is to drill it out with a carbide ball nose end mill. For an M4x.7 tap you can use a 1/8 end mill. Instead of using the quill, use the hand crank and feed the table up slowly. ...

获取价格

Help! Best way to remove broken .062 carbide drill bit from piece?

Use a carbide end mill to SLOWLY mill through the drill. Use ample coolant. The end mill will likely chip/break once the drill is separated into 2+ pieces. Once the drill is in pieces, grab a tweezers or pliers (depending on the hole size) and remove the remainder of the drill with those.

获取价格

Removing a broken carbide drill Page 2 - Practical Machinist

2015/12/15 Just recently I broke a 1/8" carbide drill about .625 deep in a hole. I was able to remove it by using a .125" ballnose end mill at 2078 rpm, 3 ipm,.0015 axial doc, with a circular path .010" oversize per axial stepdown. Lots of thru coolant and flood coolant. I'm not sure how helpful this will be to you 12 days late and you depth is 3".

获取价格

Removing broken 1/16th inch drill bit? : r/Machinists - Reddit

A carbide endmill or carbide drill ran very gently can probably turn it into dust. I have removed some stuck taps from existence doing this. Its a balancing act though, you need to make chips but also not break the tool.

获取价格

broken .062 drill bit removal? The Muzzleloading Forum

2020/3/13 Rich44, from your lips to Gods ear!. at this juncture your suggestion is about the only way. using a carbide ball end mill. no way to heat the end of the bit as it is below the surface of the flat. i have a buddy in town so i guess it's down off the mountain and to town again. twice to town in a month! gives me the heebee jeebees!

获取价格

broken .062 drill bit removal? Page 2 The Muzzleloading Forum

2004/4/12 Took both a 1/16 and 1/8 carbide ball end mill and relived the one end to get the needed cutting depth. That shows on left side, right side is original configuration. Will be sent out tomorrow. Start with the right side first and get it established and after drilling that depth flip the cutter over. Make sure to use the stop and use high rpm.

获取价格

Removing broken screws from insertable tooling

2012/7/9 Take an old 1/8 ballnose end mill or better yet grind a left hand spade drill from an old 1/8 end mill shank. .....(we use leftover carbide, snap off the end in a vise and grind a point and flats to make a crude left hand spade). Put the B-port in

获取价格

General Removing a broken drill bit - Practical Machinist

2007/7/6 Working on a simple steam/air engine today and I had to drill a .082" dia hole at a depth of .625" in 1018 mild steel. I pecked at the hole, used cutting fluid, cleared the chips etc. and still managed to break the bit of in the hole. The bit broke inside the hole, leaving no stub to grab ahold of. Are there any tricks to removing a broken bit?

获取价格

How do I extract a broken drill bit from a deep hole? - CNCzone

2011/9/22 Or try to drill it out with a carbide bit down the existing pilot hole. This may not work because a carbide drill should not be used on a pilot hole as there is a good chance the cutting edge will chip at the edges of the pilot hole and then you might have a broken carbide drill in the top end of the hole.

获取价格

General - Archive Blind dowel pin removal - Practical Machinist

2002/2/19 We usually drilled through the center of the dowel, but started the hole with a carbide ball endmill. once under the skin, any HSS should do the job. After that, fill the hole with grease or oil --remove the air also ! and then take a pin punch that is .001 smaller than the hole, and put some grease in the hole and hit the punch.

获取价格

Help Removing stuck broken drill bit : r/metalworking - Reddit

What’s everyone’s preferred method of removing broken drill bits from steel. I have some 3/8 mild steel plate I needed an 1/8th inch hole and the only bit I could find was a cheap one. It snapped in the hole. ... it can be machined out if you have access to carbide and a mill, anything without enough rigidity will just shatter your carbide ...

获取价格لفة كسارات الفحم

فصل التعويم الترشيح equipoproceso كسارات

خرد کردن pilo های گیاهان گیاهان دارویی

سحق مصنع مصنع في دبي

الفلسبار سحق التفكك الهند

آلة كسارة للمواد مربعة

تولید کنندگان کارخانه سنگ شکن در کره جنوبی

مسحوق أكسيد الكالسيوم الهيدروليكية كسارة مخروطية

أين يمكنني شراء آلة لجعل pasteles

آلة طحن الإسمنت الصغيرة

المعدات لمحطات الفحم

معمل تكسير كربونات الكالسيوم في الأردن

تكلفة رأس المال مصنع مطحنة الذهب

ميتكو تكسير وتشكيل المنتجات

صفحة تفاصيل مشروع منجم الفحم بنجا

تأثير محطم Cedarapids

مضمار خيول الفلات للبيع في الامارات

على مزيج الخصائص لغسل الفحم وتصميم المصنع خلع الملابس

الصين مصنع جدير بالثقة رخيصة الكسارات المخروطية 48 بوصة

الات صنع مواد البناء في الجزاءر

ما هو ميزة تأثير محطم

آلات الحجارة المستخدمة

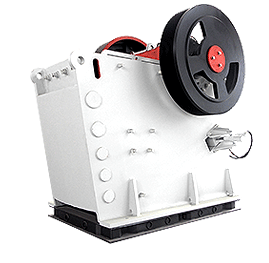

البناء البناء من كسارة الفك مع أجزائها

بيع كسارة كسارة النباتات

الصخور كسارات موقع التعدين

سحق الحجر الرملي الموردين

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20