الحار منتجات

ملكنا الإخبارية

floatation process iron ore

(PDF) Flotation of Iron Ores: A Review - ResearchGate

2019/11/19 Overview of the Groveland Mine iron ore beneficiation process, utilizing direct flotation in acidic conditions (based on Houot 1983). Overview of the iron ore beneficiation process in the Qidashan ...

获取价格

Flotation of Iron Ores: A Review - Taylor Francis Online

2019/11/19 A tremendous amount of research has been done on refining the flotation process for iron ore and designing the reagents which go into it.

获取价格

New perspectives in iron ore flotation: Use of collector reagents ...

2021/8/15 In both cases, the flotation process adopted is a reverse cationic process with a preliminary desliming stage of flotation feed to remove materials with particle sizes below 10

获取价格

Froth Flotation of Iron Ores - article.sapub

2012/1/2 With the depleting reserves of high-grade iron ore in the world, froth flotation has become increasingly important to process intermediate- and low-grade iron ore in an attempt

获取价格

An overview of the beneficiation of iron ores via reverse cationic ...

2014/3/10 Research regarding iron ore flotation began in 1931, demonstrating that reverse cationic flotation is a very efficient method for beneficiating oxidised iron ores. ... In general,

获取价格

Flotation Process and Techniques Involved in Iron Ore Slurry

the froth flotation process: collector, frother, and modifier. First, the “Collector” is added to the iron ore slurry for selectively coat the iron oxide particles, makes the surface hydrophobic. The

获取价格

Exploring Low-Grade Iron Ore Beneficiation

2024/8/2 The cationic reverse flotation process was invented by the U.S. Bureau of Mines and is widely utilized in iron ore industries globally . In this technique, amine collectors float silica gangue minerals like quartz, while

获取价格

Evaluation of the Crago flotation process to recover the iron

2024/4/1 In this context, ArcelorMittal stands as one of the world's premier producers of iron ore. Sporting a geographically diverse array of iron ore and coal assets, the company

获取价格

Treatment and Recycling of the Process Water in Iron Ore

2017/8/8 1. Introduction. Iron ore resources are extremely rich in China, but most of them belong to complex ultrafine iron ore with high content of impurities [].Reverse flotation has

获取价格

Flotation of Iron Ores: A Review - Semantic Scholar

2019/11/19 ABSTRACT A tremendous amount of research has been done on refining the flotation process for iron ore and designing the reagents which go into it. This paper reviews

获取价格

The Flotation Process Sepro Labs - YouTube

观看视频1:332021/1/6 How familiar are you with the flotation process? Our new video shows how this process can separate valuable minerals from slurry for recovery.

获取价格

Reagents in iron ores flotation - ScienceDirect

2005/2/1 Primary fatty amines, utilised in the pioneer USBM process, are no longer employed in the flotation of iron ores. They were modified with the insertion of the polar group (O–CH 2) 3 between the radical R and the polar head NH 2 of the primary amine. Due to the presence of the covalent bond C–O, characteristic of the organic function ether, reagents

获取价格

Flotation of Iron Ores: A Review - ResearchGate

The flotation of iron ore was first investigated in America starting in 1931 (Iwasaki 1983, 1999; Uwadiale 1992). ... Overview of the iron ore beneficiation process in the Qidashan concentrator ...

获取价格

New perspectives in iron ore flotation: Use of collector reagents ...

2021/8/15 In both cases, the flotation process adopted is a reverse cationic process with a preliminary desliming stage of flotation feed to remove materials with particle sizes below 10 µm (slimes) that are harmful to the iron ore flotation process (Filippov et al., 2014).

获取价格

Process Evaluation of an Iron Ore Operation Using the ... - MDPI

2021/5/31 The Brucutu iron ore mine (Minas Gerais, Brazil) is Vale‘s largest iron producing operation achieving around 21 million tons per annum. Evaluation of flotation performance is of high importance as even small gains can lead to large monetary benefits. Cell-by-cell samples of the froth products, selected feed and pulp-products were analyzed for flow rate, particle size

获取价格

Treatment and Recycling of the Process Water in Iron Ore Flotation

2017/8/8 1. Introduction. Iron ore resources are extremely rich in China, but most of them belong to complex ultrafine iron ore with high content of impurities [].Reverse flotation has been proved to be an efficient process for economic reasons [2 – 6].In order to ensure iron concentrate grade and iron recovery, a large number of processing reagents are selected and applied in

获取价格

Improving recovery of iron using column flotation of iron ore

2020/11/1 In general, the industrial flowsheets for the beneficiation of itabirite iron ores from the Quadrilátero Ferrífero (Minas Gerais state) in Brazil involves grinding, desliming, magnetic separation and cationic reverse flotation using both mechanical and columns flotation cells. At Brazilian plants, it is estimated that Fe losses generated at the slimes stage range

获取价格

Froth flotation - Wikipedia

Froth flotation to separate plastics, Argonne National Laboratory Froth flotation cells to concentrate copper and nickel sulfide minerals, Falconbridge, Ontario. Froth flotation is a process for separating minerals from gangue by exploiting differences in their hydrophobicity.Hydrophobicity differences between valuable minerals and waste gangue are

获取价格

Froth Flotation of Iron Ores - article.sapub

2012/1/2 With the depleting reserves of high-grade iron ore in the world, froth flotation has become increasingly important to process intermediate- and low-grade iron ore in an attempt to meet the rapidly growing demand on the international market. In over half a century’s practice in the iron ore industry, froth flotation has been established as an efficient method to remove

获取价格

1 Froth Flotation – Fundamental Principles

After carrying out a froth flotation separation, the products are as shown in Table 1. Using this data, calculate: (a) Ratio of concentration (b) % Metal Recovery (c) % Metal Loss (d) % Weight Recovery, or % Yield (e) Enrichment Ratio Table 1: Grade/recovery performance of a hypothetical copper ore flotation process.

获取价格

How Flotation Machine works, flotation machine, ore dressing

Type:flotation machine Applied Materials: Quartz, gold, silver, copper and iron ore etc. non-ferrous metals, ferrous metals, coal, fluorite, talc, lead, zinc...

获取价格

Flotation Process and Techniques Involved in Iron Ore Slurry

Typically there are 3 different types of chemicals that are used in the froth flotation process: collector, frother, and modifier. First, the “Collector” is added to the iron ore slurry for selectively coat the iron oxide particles, makes the surface hydrophobic.

获取价格

Investigation of Adsorption Mechanism of Reagents (Surfactants) System ...

2018/7/1 In this paper, the reagents/surfactants used in direct and reverse flotation process of iron ore has been reviewed with the aim of identifying their usefulness and limitations coupled with adsorption mechanism and surface chemistry. This paper provides a glimpse of study on effect of other parameters like pH, chemistry and composition of pulp ...

获取价格

Evaluation of the Crago flotation process to recover the iron

2024/4/1 In this context, ArcelorMittal stands as one of the world's premier producers of iron ore. Sporting a geographically diverse array of iron ore and coal assets, the company finds itself strategically poised to cater to a network of steel plants while also meeting the demands of the global iron ore market beyond its borders (Barbosa et al.,2017).In this scenario, the Mont

获取价格

How Flotation Machine works, flotation machine, ore dressing

观看视频5:362014/5/22 Type:flotation machine Applied Materials: Quartz, gold, silver, copper and iron ore etc. non-ferrous metals, ferrous metals, coal, fluorite, talc, lead, zinc...

获取价格

Flotation Process and Techniques Involved in Iron Ore Slurry

Typically there are 3 different types of chemicals that are used in the froth flotation process: collector, frother, and modifier. First, the “Collector” is added to the iron ore slurry for selectively coat the iron oxide particles, makes the surface hydrophobic.

获取价格

Investigation of Adsorption Mechanism of Reagents (Surfactants) System ...

2018/7/1 In this paper, the reagents/surfactants used in direct and reverse flotation process of iron ore has been reviewed with the aim of identifying their usefulness and limitations coupled with adsorption mechanism and surface chemistry. This paper provides a glimpse of study on effect of other parameters like pH, chemistry and composition of pulp ...

获取价格

Evaluation of the Crago flotation process to recover the iron

2024/4/1 In this context, ArcelorMittal stands as one of the world's premier producers of iron ore. Sporting a geographically diverse array of iron ore and coal assets, the company finds itself strategically poised to cater to a network of steel plants while also meeting the demands of the global iron ore market beyond its borders (Barbosa et al.,2017).In this scenario, the Mont

获取价格

Design, Modeling, Optimization and Control of Flotation Process

The ultimate goal of a flotation process is to achieve the economically optimum combination of the desired mineral grade and recovery in the final concentrate from a feed of varying composition. The industrial operation of froth flotation faces many challenges, such as sudden decreases in the recovery and grade of recovered materials. The quality of the final concentrate determines the

获取价格

Minerals Special Issue : Iron Ore Flotation - MDPI

2021/5/12 Iron ore flotation is a key technique to concentrate intermediate-low-grade ore, in order to reach the market requirements for higher-grade concentrates of iron. The presence of some impurities in addition to quartz in iron ore, aluminium silicates, and minerals containing phosphorus impair productivity in the steel industry and have an impact ...

获取价格

Exploring Low-Grade Iron Ore Beneficiation Techniques: A ... - MDPI

2024/8/2 In India, China and Brazil, iron ore flotation is a commonly practiced separation technique with process control regarded as an integral part of flotation process operations. Mintek in South Africa developed an advanced flotation stabilization and optimization system, which was installed in Brazil’s Vale’s Cauè iron-ore-processing plant ...

获取价格

Multivariate modeling and optimization of the reverse cationic ...

2024/1/1 The modification of starch via ammonium hydroxide solution proved to be effective as a final application in an iron ore depressant in the flotation process with a separation of approximately 80 %. It is possible, through the NBI, to verify that the optimization carried out, in numerous different process steps, and the validation was considered ...

获取价格

The Characteristics of Iron Ore Slimes and Their Influence on

2020/7/30 The flotation has been successfully applied to process the iron ore for the particle size (Ps) from 10 µm up to 150 µm. The presence of the slimes (Ps < 10 µm) is harmful on the reverse flotation of quartz, so they are usually prior removed by hydrocyclones. The main effects of the presence of slimes on the flotation are related to the increase on reagents

获取价格

Flotation Characteristics of Amphibole-Type Oxidized Iron Ore

2023/8/8 To explore the flotation feasibility and flotation law of iron minerals from amphibole-type iron oxide ore with full-size minerals, a systematic study on the flotation behaviors of single minerals hematite, quartz, and amphibole was carried out with the anionic reverse flotation system. The effects of collectors, depressants, activators, and pH on the floatabilities

获取价格

Four Points To Improve Tin Ore Flotation Recovery Rate

2024/11/11 Recovery is the percentage of valuable minerals successfully extracted from ore during the flotation process. During the flotation process, the pH value of the solution, particle-bubble interaction, metal ions and flotation reagents significantly impact the flotation of tin ore. In this article, we will explore four key points that can help ...

获取价格

Effects of surfactants combination on iron ore flotation

2022/12/1 1. Introduction. Froth flotation is the most important process to produce superconcentrates from low-grade oxidized iron ores. The efficiency of the process strongly depends on bubble size and froth stability, requiring the use of frothers.

获取价格

How to use Column Flotation to Reduce Silica - 911Metallurgist

2018/5/1 The flotation rate constant is also affected by particle size. Many iron ore concentrators use the quantity of +100 mesh (.15mm) material in the flotation feed as a measure of the performance of the grinding circuit. 100 mesh particles are well within normal flotation range and present no particular problems.

获取价格

Froth Flotation of Iron Ores - Semantic Scholar

2012/8/31 With the depleting reserves of high-grade iron ore in the world, froth flotation has become increasingly important to process intermediate- and low-grade iron ore in an attempt to meet the rapidly growing demand on the international market. In over half a century's practice in the iron ore industry, froth flotation has been established as an efficient method to remove

获取价格الكسارات المتنقلة من جهة ثانية في دبي

باكستان التصنيع المحلي من كسارة

مطحنة المخارط

تستخدم على نطاق واسع كسارة الفك المحمول

مطحنة للرمل السيليكا طحن في ناميبيا

محطة تكسير الحجارة 40tph

المطاحن الكالسيوم مطحنة الكرة كربونات صنع في ألمانيا

أمريكية آلة من صنع الفلفل الحار طاحونة الطحن

تستخدم الخرسانة الجاهزة العاصفة للبيع

شركة مطاحن المنوفية

نموذج طلب رخصة محجر كسارة

شاشات trommel للبيع nz

مصنع لفحص الرخام المكسر

كسارة الفك للter الصين

يبحث كسارة مستعملة

آلات سحق البنتونيت شراء كسارات الحجر

Kos محطم تشغيل الحجر

ادوات خفر

تايلاند كسارة الفك من جهة ثانية التنظيف الذاتي

كفاءة عالية المتداول واضعا الكرة كرات طاحونة كسارة مطحنة الكرة

البساطة تهتز الشاشات MercadoLibre مطاحن بيع السكر إلى كاليفورنيا

المواد الخام من اختلاط ملموسة

أفضل كسارة الحجر الجيري الراتنج الطلاء

الة طحن البلاط 90

آلة تكسير الرخام للبيع

ستون شستشو فلزی

حول لدينا

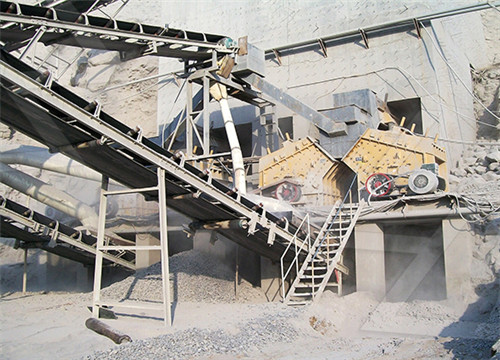

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20