الحار منتجات

ملكنا الإخبارية

1 demolition brick and slag crushing

Laboratory Tests on Compaction and Crushing Behaviors of

main components in a slag–clay mixture are concrete and brick, whose critical crushing stress is much lower than that of gravel. Moreover, brick absorbs much more water than gravel during

获取价格

Construction and demolition waste generation and properties of

2018/6/10 Fig. 1 explains the schematic flow of the materials during the ... 2000 standard allows the use of crushed over burnt bricks and slag in plain concrete unless affects the

获取价格

Upcycling of demolition material from concrete and brick for the ...

2023/8/22 This paper deals with the production of artificial aggregates based on the recycled fine fraction (≤ 4 mm) from construction demolition waste. Concrete powder, brick

获取价格

Construction and Demolition Waste as Recycled Aggregates in

2019/12/3 Vavro et al. used crushed clay bricks, and OPC concretes as the RA in slag-based concretes activated by the combination of sodium hydroxide and sodium silicate. It was

获取价格

Investigation into Creep Characteristics and Model of

and the proportion of brick slag in the CDW is large—the ratios of the samples used in the following test are set as 4:5:1, 5:4:1, 6:3:1, and 7:2:1 (brick slag: concrete slag: mortar slag),

获取价格

Effect of Brick Aggregate Content on Performance of Recycled

2024/5/29 A brick aggregate content less than 80% had little effect on the gradation of mixed recycled aggregate. During the compaction process, the recycled aggregate with a

获取价格

Effect of brick-based construction and demolition waste on the ...

2023/11/1 CDW coarse aggregate was fabricated by crushing and sieving brick-based CDW, the physical properties and performances of brick-based coarse aggregate were shown

获取价格

Taking Down the Brick Wall - Recycling Today

2010/4/20 Recyclers report that the mortar contained in bricks causes little hassle in the crushing process. “The total amount of mortar visible in the final recycled product is greatly

获取价格

Preparation of High-Performance Brick from Construction and

Recycled aggregate prepared from construction and demolition waste (CDW) through sorting, crushing and screening process was mixed with an eco-cement (mainly from high calcium fly

获取价格

Properties and composition of recycled aggregates from

2014/8/29 The global market for construction aggregates is expected to increase 5.2% this year, and again next year, up to 48.3 billion tonnes [1].In the United States, the Environmental

获取价格

Construction and Demolition Waste as Recycled Aggregates in

2019/12/3 Vavro et al. used crushed clay bricks, and OPC concretes as the RA in slag-based concretes activated by the combination of sodium hydroxide and sodium silicate. It was revealed that after experiencing 100 freeze and thaw cycles, the loss of mass in the composition containing RA from crushed old OPC concrete was three times less than the ...

获取价格

Investigation into Creep Characteristics and Model of

and the proportion of brick slag in the CDW is large—the ratios of the samples used in the following test are set as 4:5:1, 5:4:1, 6:3:1, and 7:2:1 (brick slag: concrete slag: mortar slag), and pure brick slag is selected as the comparison. Table 1. Field mass ratio of recycled construction and demolition waste (CDW) filler. Sample Brick slag ...

获取价格

Impact of Induction Furnace Steel Slag as Replacement for Fired

2021/10/21 2.1. Materials Properties and Mix Design. The materials used to cast the reinforced concrete (RC) beams for the flexural test and specimens for durability test were binder (CEM II/A-M, 42.5 N [], consists of 80–94% clinker, 6–20% slag, fly ash, and limestone, and 0–5% gypsum), water, coarse aggregate (fire clay brick aggregate-FCBA and induction furnace steel

获取价格

Upcycling of demolition material from concrete and brick for the ...

2023/8/22 This paper deals with the production of artificial aggregates based on the recycled fine fraction (≤ 4 mm) from construction demolition waste. Concrete powder, brick powder and their combination were used to produce aggregates through pelletisation using sodium silicate solution as an activator. For all aggregates, efficiency, bulk crushing

获取价格

Crushing Recycling - Independence Excavating

Crushing of 50,000 tons of brick, block and concrete generated by our demolition team at the former DTE Shenango Coke Plant. View Project DTE Shenango Coke Plant ... Air cooled blast furnace slag processing in Cleveland Ohio. 800,000 tons crushed and produced annually.

获取价格

Chemical stabilization of demolition wastes in pavement bases

The stabilization of road bases is a critical part of geotechnical research for developing new methods of sustainable road construction for the future. This study evaluated the feasibility of using one-part fly ash (FA) and slag (S) based geopolymers for stabilizing construction and demolition (CD) aggregates with major significances included reduction in landfill wastes and

获取价格

Stabilization of PET plastic-demolition waste blends using fly

2021/5/17 This study evaluates the main geotechnical parameters of the geopolymer-stabilized blends comprising of two main CD types, namely recycled concrete aggregate (RCA) and crushed brick (CB), in blends with 5% PET fragments (% by mass). 10%Fly ash (FA), 10%Slag (S) and 5%FA + 5%S were used as the precursors at a fixed liquid activator to

获取价格

Development of sustainable alkali-activated slag bricks with high ...

2024/6/7 The chemical compositions of the slag, RCF, and CRCF are presented in Table 1.It can be seen that the primary active constituents in these materials, namely CaO, SiO 2, and Al 2 O 3, are contained in the slag at a proportion of 89.7 %.When comparing RCF and CRCF before and after carbonation, an increase of 2.09 % in the loss on ignition (LOI) of RCF is

获取价格

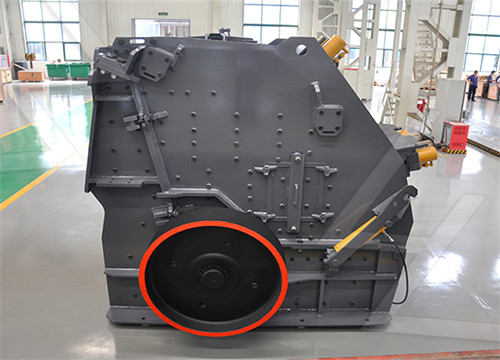

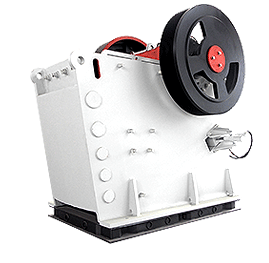

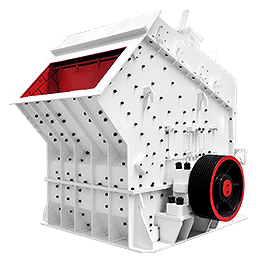

Small Construction Waste Brick Slag Crushers - JXSC Rock Crusher

double roller crusher. Jaw crusher; Feed size is <500mm; production capacity: 1-240t/h. Final product specifications are 10-200mm. Although the jaw crusher is usually for primary crushing, it is suitable for processing brick slag in small-scale applications, especially when the raw material is large. After that, it cooperates with other types of crushers for further crushing.

获取价格

Taking Down the Brick Wall - Recycling Today

2010/4/20 When crushing brick material, contractors must be aware of the difference in density between brick and the concrete and asphalt material they may be more accustomed to crushing. “Say a contractor has a normal setting on an impactor, where the concrete will come out at 1 inch, 1.5 inches,” Royce says.

获取价格

Unveiling the Features and Uses of Rock Crusher

2024/3/31 They are employed for the primary crushing of raw ore, reducing the ore to a manageable size for further processing in mills or concentrators. Construction and Demolition. Rock crushers are essential equipment in construction and demolition projects, where large rocks and debris need to be crushed into smaller pieces for disposal or recycling.

获取价格

cleaning slag brick - hcrot

HCR170D is a new type of high-tech equipment used for precision operations in high-risk environments, utilizing the organic integration of a tracked motion chassis, a smooth hydraulic system, a multi-parameter sensing system, etc. Flexibility in carrying out all-round crushing or demolition operations in hazardous areas is its characteristic.

获取价格

Construction Brick Slag Crushing And Recycling Plant

2024/2/2 If you want to invest in brick slag crushing plants, crusher equipment is the key. Currently, there are two main types of equipment available for brick slag crushing: fixed crushers and mobile crushers. 1. Fixed brick slag crushing plant. The fixed bricks slag crushing plant usually includes jaw crushers, cone crushers, and impact crushers.

获取价格

Taking Down the Brick Wall - Recycling Today

2010/4/20 When crushing brick material, contractors must be aware of the difference in density between brick and the concrete and asphalt material they may be more accustomed to crushing. “Say a contractor has a normal setting on an impactor, where the concrete will come out at 1 inch, 1.5 inches,” Royce says.

获取价格

Unveiling the Features and Uses of Rock Crusher

2024/3/31 They are employed for the primary crushing of raw ore, reducing the ore to a manageable size for further processing in mills or concentrators. Construction and Demolition. Rock crushers are essential equipment in construction and demolition projects, where large rocks and debris need to be crushed into smaller pieces for disposal or recycling.

获取价格

cleaning slag brick - hcrot

HCR170D is a new type of high-tech equipment used for precision operations in high-risk environments, utilizing the organic integration of a tracked motion chassis, a smooth hydraulic system, a multi-parameter sensing system, etc. Flexibility in carrying out all-round crushing or demolition operations in hazardous areas is its characteristic.

获取价格

Construction Brick Slag Crushing And Recycling Plant

2024/2/2 If you want to invest in brick slag crushing plants, crusher equipment is the key. Currently, there are two main types of equipment available for brick slag crushing: fixed crushers and mobile crushers. 1. Fixed brick slag crushing plant. The fixed bricks slag crushing plant usually includes jaw crushers, cone crushers, and impact crushers.

获取价格

Effect of brick-based construction and demolition waste on the ...

2023/11/1 Brick-based construction and demolition waste (CDW) was successfully used to prepare lightweight aggregate concrete, and the effects of the CDW mineral admixture and aggregate on workability, hardened performance, microstructure and influence mechanism were also investigated. The results indicated that replacing lightweight aggregate from 0% to 100%

获取价格

Aggregates Recycling – Overhall

We aim to recycle 100% of inert construction and demolition waste. Crushing, screening and 8 wheel tipper hire available. Other materials available upon request. free tip for inert brick, concrete and tarmac in Scunthorpe. MOT type 1 blast furnace slag; MOT limestone type 1; MOT recycled type 1; Fill sand; Building sand; Crushed brick 6f5 ...

获取价格

Bobs/Angels - Crushed Stone and Slag Management :

I was figuring to do crushing at the mining site, train the crushed ore to a centralized refining setup, and seperately train the stone from the site and slag from refining to a separate recovery setup. but I'm starting to doubt that plan now. I was originally figuring to try to use it as a source of Uranium for stepping up to nuclear.

获取价格

Investigation into Creep Characteristics and Model of

2020/3/3 Recycled Construction and Demolition Waste Used in Embankment Filler Zhe Li 1,*, Shihao Yan 1, ... a microscopic point of view. The filler with a 7:2:1 ratio (brick slag: concrete: mortar) has the densest ... Recycled aggregates are obtained by the crushing and screening of CDW, so research into the ...

获取价格

Upcycling of demolition material from concrete and brick for the ...

2023/8/22 This paper deals with the production of artificial aggregates based on the recycled fine fraction (≤ 4 mm) from construction demolition waste. Concrete powder, brick powder and their combination ...

获取价格

Effect of brick-based construction and demolition waste on the ...

2023/11/1 CDW coarse aggregate was fabricated by crushing and sieving brick-based CDW, the physical properties and performances of brick-based coarse aggregate were shown in Fig. 1 and Table 2. These coarse aggregates mainly composed of broken bricks, gravels, and old mortars, and most of the aggregates were polygonal, and the density was lower than that ...

获取价格

Preparation of High-Performance Brick from Construction and Demolition

Recycled aggregate prepared from construction and demolition waste (CDW) through sorting, crushing and screening process was mixed with an eco-cement (mainly from high calcium fly ash, granulated blast-furnace slag and clinker), antifreeze additives and water, forming high-performance load bearing brick. The product prepared conforms to GB/T21144-2007

获取价格

Construction waste crushing and screening equipment.

Construction waste slag–clay mixture has been widely used as filling material, which has significant social, economic, and environmental protection benefits.

获取价格

What is the use of the demolition of the brick slag, brick slag

Multifunctionality: besides being used for crushing brick slag, the equipment can also be used for crushing other hard materials, such as waste concrete, waste asphalt and so on. By using the brick slag flow crusher, the brick slag produced by demolition can be turned into treasure, realizing the recycling of resources.

获取价格

Construction and demolition waste - ScienceDirect

2019/1/1 In general, CDW includes a wide variety of materials that are generated from different sources, such as concrete, bricks, bituminous materials, soil, steel, wood and gypsum that may come from the construction of new buildings, roads and bridges and other structures, renovation-related activities, demolition of end-of-life structures and also from natural or man

获取价格المسمار الناقلون الجاف بالجملة نقل المواد

آني برادكين كسارة مخروطية

معايير api لتكسير مكعبات الخرسانة

المغذية المسمار حساب الناقل للتصميم

فواصل الرمال الحديد ل بيع في مصر

حار بيع في جنوب آسيا كسارة تأثير خام الحديد بسعر معقول

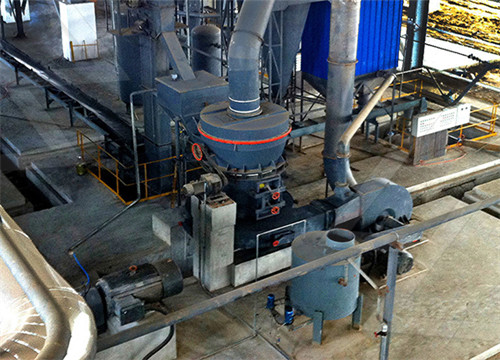

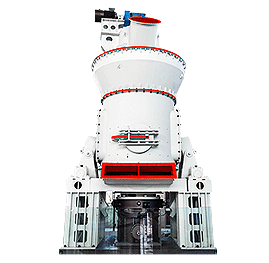

ريموند مطحنة قدرة لالجيري

حساب قدرة الصيغ الفك محطم

لا يتم تركيز خام النحاس عن طريق الغسيل الهيدروليكي

especificação do moinho de bolas pequenas pdf

الاسمنت مطحنة عمودية اليابان

محطة كسارة الفك المحمول نوع المحمولة سلسلة

معدات الصحافة لفة لكسارة الأسمنت

ماليزيا الفك كسارة الصخور

حجر كسارة عصابة عداء

كسارة مخروطية صغيرة للبيع في كازاخستان

طرق مالجة خامات الذهب بطريقة الطرد المركزي

محرك الديزل 520ton سعر كسارة الصخور المحمولة الصغيرة

دراسة حول أداء الغبار كسارة

ذروة الشراء على الانترنت أجل محطم على الانترنت

كيفية تنظيف فناء الأسمنت

لفاف محطم هنغاريا

شركة النصر للتعدين خام الإلمنيت

الفحم سحق سعر المصنع

كسارة الأسمنت في كوتبوتلي

السعري كسارة باتو بارا كيسيل دي الهند

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20