الحار منتجات

ملكنا الإخبارية

beneficiation of coal process

Coal Beneficiation Technology - 2007 Initiatives, Policies and

Coal Beneficiation. Coal beneficiation is a process by which the quality of raw coal is improved by either reducing the extraneous matter that gets extracted along with the mined coal or

获取价格

Beneficiation - an overview ScienceDirect Topics

The beneficiation process of coal fly ash has proved to be beneficial in terms of economic and environmental aspects in the recovery of unburnt carbon, cenospheres, and magnetic

获取价格

What Is Coal Preparation? - Energy.gov

Why Coal Preparation? Remove extraneous, non-combustible material. Ash reduction. lower particulates. reduced ash handling at power station. Sulfur reduction (lower SO X emissions)

获取价格

Mineral Beneficiation and Processing of Coal SpringerLink

1 Sizing Devices2 Washing/Cleaning Devices3 Dewatering DevicesSizing units are common in the processing of coals that are used throughout the circuit to perform different jobs. In the present-day coal preparation plants, sizing is done primarily for the following reasons: 1. Removal of trash material or oversized boulders. 2. Separation of coal particles based on the size required by the concentration unit. 3...

Coal beneficiation: theory and practice - ScienceDirect

2023/1/1 Sizing coal is the process of segregating coal lumps that are similar in size. Coal passes over one or more vibrating screens/grates and the larger sizes not passing through

获取价格

Froth flotation beneficiation and physiochemical characterization

2022/10/31 Coal beneficiation is the process of improving the fixed carbon content to increase the calorific value of the coal by removing the mineral matters. It involves the

获取价格

US4412842A - Coal beneficiation process - Google Patents

In accordance with the present invention, a process for the beneficiation of coal is provided which washes the coal during slurrying, impregnates the coal and concentrates the slurry to a high

获取价格

COAL BENEFICIATION DRY METHODS - fossil.energy.gov

COAL BENEFICIATION DRY METHODS. Rick Honaker, University of Kentucky Gerald (Jerry) Luttrell, Virginia Tech. U.S.-India 6th Coal Working Group Meeting L’Enfant Plaza Hotel

获取价格

Coal Beneficiation Process Diagram - 911Metallurgist

2016/4/12 Remarks on Coal Beneficiation Process and Diagram. “Sub-A” Coal Flotation Systems have been successful for recovery of both coarse and fine coal. It is important,

获取价格

COAL BENEFICIATION - National Energy Technology

• Developing process options for broadening the slate of products produced from a coal mine. • Enhancing the value of domestic coals as fuels for ... Coal beneficiation technologies create cost-competitive, upgraded coal feedstocks that increase the value of existing coal assets as power plant fuels, address technical barriers ...

获取价格

(PDF) Beneficiation of Coals: A Review - Academia

Coal beneficiation by chemical treatment Coal beneficiation by agglomeration techniques Beneficiation of bituminous and lignite coals can be done by agglomeration using binding oils containing either p-xylene, or deodorized rectisol naphtha and the reduction in ash content has been studied with respect to particle size, mixing speed, mixing ...

获取价格

Reclaiming and Recycling Coal Ash for Beneficial Use - TN.gov

2019/5/16 John Castleman, P.E. Senior Process Engineer May 16, 2019 . WWW.SEFAGROUP.COM . WWW.SEFAGROUP.COM STAR Fly Ash Beneficiation Fly Ash Byproduct Source Gypsum Operations Beneficiation Raw Feed Source ... Coal Ash Beneficiation Commercial Processes Electrostatic Separation • Separates Unburned Carbon • Two Product

获取价格

Froth flotation beneficiation and physiochemical characterization

2022/10/31 Coal beneficiation is the process of improving the fixed carbon content to increase the calorific value of the coal by removing the mineral matters. It involves the combustion behavior, reducing slagging, fouling characteristics, and minimizing particulate pollutants and gas emissions (Behera et al., 2018; Meshram et al., 2015).

获取价格

DRY BENEFICIATION OF COAL—A REVIEW - Semantic Scholar

Coal continues to play a major role in the economic development of a country, especially in metallurgical industries and conventional power generation plants. For effective utilization of high ash coals, it is necessary to beneficiate them. The wet beneficiation process for coal cleaning is currently the predominant method of purification of coal in the world.

获取价格

Dry beneficiation of coal - ScienceDirect

1984/10/1 The quantities of coal being beneficiated and the levels of beneficiation required are increasing while the quality of raw coals is decreasing. Although coal is currently cleaned with the minimum of size reduction, fine particle processing, recovery, and tailings disposal are already major problems. Furthermore, adequate water resources are not ...

获取价格

Beneficiation of pyrite from coal mining - ScienceDirect

2016/12/15 In this context, this paper suggests methods of concentration of pyritic waste to raise its iron disulfide content and to contribute to the sustainability of the coal extraction process. 2. Experimental procedure2.1. Materials. The pyrite from the coal waste was collected in the city of Treviso/SC, Brazil.

获取价格

Beneficiation of Fine Coal: Froth Flotation Efficiency - Coaltech

The process was not used in the Witbank/Middelburg area since the coal from this region was generally considered “non-floating”. When spirals were introduced in the early 1980s, the fine coal that would normally have been subjected to froth flotation was sent to the more economical spirals at plants such as Grootegeluk.

获取价格

Coal Processing - Multotec

Coal processing or coal beneficiation uses physical (mechanical) and/or chemical methods to remove rocks, dirt, ash, sulphur and other contaminants and unwanted materials to produce high-quality coal for energy in both local and export markets.. Multotec manufactures a complete range of equipment for coal processing plants, from the Run of Mine (R.O.M) stockpile to the tailings

获取价格

Transformation in energy content of non-coking coals during ...

Successful correlation studies comparing the properties of non-coking coal before and after beneficiation are crucial in establishing the efficacy of the Sink-and-Float Washability Process to tailor non-coking coal for specific industrial applications [18]. The goal is to offer a sustainable solution to India's reliance on coking coal imports.

获取价格

Coal Beneficiation - sustainable-carbon

The need for coal beneficiation • Removal of ash, water and contaminants raises performance, resulting in cleaner thermal coal power • High quality feedstock is needed to fully benefit from HELE technology • Reduces carbon footprint in life cycle analysis where transport is included • Higher value and non-energy products can be produced lignite subbituminous bituminous

获取价格

CFD intensification of coal beneficiation process in gas-solid ...

2020/2/1 Coal beneficiation process in gas-fluidized beds involved the coexisting motion of fine medium particles, large coal particles and gas phase. Such a complex system is widely used in chemical engineering including biomass pyrolysis, fuel particles combustion and mineral separation [[28], [29], [30]].

获取价格

Recent advances in the beneficiation of ultrafine coal particles

2018/9/1 According to Wang et al. [13] and Khayrutdinov et al. [14], the mineral coal beneficiation process must face the organic materials of associated minerals in the form of nanoparticles and ultrafine ...

获取价格

Transformation in energy content of non-coking coals during ...

Successful correlation studies comparing the properties of non-coking coal before and after beneficiation are crucial in establishing the efficacy of the Sink-and-Float Washability Process to tailor non-coking coal for specific industrial applications [18]. The goal is to offer a sustainable solution to India's reliance on coking coal imports.

获取价格

Coal Beneficiation - sustainable-carbon

The need for coal beneficiation • Removal of ash, water and contaminants raises performance, resulting in cleaner thermal coal power • High quality feedstock is needed to fully benefit from HELE technology • Reduces carbon footprint in life cycle analysis where transport is included • Higher value and non-energy products can be produced lignite subbituminous bituminous

获取价格

CFD intensification of coal beneficiation process in gas-solid ...

2020/2/1 Coal beneficiation process in gas-fluidized beds involved the coexisting motion of fine medium particles, large coal particles and gas phase. Such a complex system is widely used in chemical engineering including biomass pyrolysis, fuel particles combustion and mineral separation [[28], [29], [30]].

获取价格

Recent advances in the beneficiation of ultrafine coal particles

2018/9/1 According to Wang et al. [13] and Khayrutdinov et al. [14], the mineral coal beneficiation process must face the organic materials of associated minerals in the form of nanoparticles and ultrafine ...

获取价格

Ultrasonic-assisted coal beneficiation: A review - ScienceDirect

2019/1/1 Therefore, it is important to upgrade the existing coal beneficiation techniques for improving the clean coal quality, and simultaneously enhance the efficiency of the process. In the past few decades, many techniques have been developed to

获取价格

Cost-Effective, Environmentally-Friendly Ash Beneficiation

In 2017, approximately 64% of the CCPs generated at coal fired power stations was recycled for beneficial use, with the majority being used for concrete products and portland ... MP618™ Multi-Process fly ash thermal beneficiation technology is unique as it addresses multiple constituents within a single process and has no waste streams. The ...

获取价格

Dry beneficiation technology of coal with an air dense-medium

2001/11/1 Dry beneficiation of coal with an air dense-medium fluidized bed is an efficient coal separation method, which uses a gas-solids fluidized bed as the separating medium, contrasting with the conventional methods of coal preparation using water as medium as in jigs. ... This process is subject to the Archimedes Law (shown in Fig. 1e) ...

获取价格

Transformation in energy content of non-coking coals during ...

Based on the study conducted on non-coking coal beneficiation, some interesting outcomes have been achieved in this study which could be valuable for industrial applications, particularly in the steel sector. ... Finally, the conclusions are, the beneficiation process yields recovery rates of 66.04 % for 1 mm to 3 mm sizes, 61.31 % for 3 mm to ...

获取价格

COST-EFFECTIVE ASH BENEFICIATION TECHNOLOGY

Currently, coal fly ash with a loss on ignition (LOI) above 6% does not meet ASTM C-618 specification. Additionally, coal ... nationwide, the MP618™ Multi-Process fly ash thermal beneficiation technology can reliably and continuously process fly ash to: Reduce LOI to < 3% Reduce ammonia content to < 60 ppm

获取价格

Progress in developments of dry coal beneficiation

2014/8/21 China’s energy supply heavily relies on coal and China’s coal resource and water resource has a reverse distribution. The problem of water shortages restricts the applications of wet coal beneficiation technologies in drought regions. The present situation highlights the significance and urgency of developing dry beneficiation technologies of coal.

获取价格

Microbial Co-processing and Beneficiation of Low-rank Coals

coal beneficiation technology, microbial coal desulfurization. This process can be described as microbiological sulfur- and ash removal from various coals and is exploited as either an alternative or a complementary process in clean coal technologies.[23] Furthermore,

获取价格

Dry beneficiation technology of coal with an air dense-medium

2001/11/1 Coal beneficiation is one of the most effective methods for removing minerals (such as gangues and pyrite) and pollutants (such as sulfur) before the burning of coal. In general, the beneficiation process of low rank coals is more difficult to achieve than that of bituminous and/or anthracite coals. However, about 50% of the world's total coal ...

获取价格

COAL BENEFICIATION DRY METHODS - fossil.energy.gov

COAL BENEFICIATION DRY METHODS Rick Honaker, University of Kentucky Gerald (Jerry) Luttrell, Virginia Tech U.S.-India 6th Coal Working Group Meeting L’Enfant Plaza Hotel Washington D.C. September 23, 2009. India’s Coal Industry Coal Production/Consumption 4th largest coal reserve

获取价格

Oil Agglomeration Towards Quality Enhancement of High-Ash

2021/5/11 In a typical coal beneficiation process, coal is subjected to a medium of defined specific gravity, containing both high-density and low-density liquids. Heavier material sinks (rejects or mineral matter) and lighter coal floats (clean coal). This specific gravity is defined by the ‘washability’ characteristics of the coal seam which is not ...

获取价格ballmill magnetite محطم للبيع

آلة كسارة الثالث

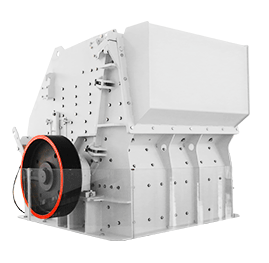

جودة عالية تأثير محطم الحجر الجيري

تقرير جدوى لمطحنة الكرة

الحجر ثلاثة أرباع

نسبة المياه هلام وأثر الرماد المتطاير على ارتفاع درجة الحرارة كظومه من الخرسانة

كيفية تكييف محرك إلى مطحنة يدوية

المبيعات المحمولة الكسارة في المغرب

consol bottle recycling south africa

أدوات رئيسية آلة طاحونة المورد

سعر كسارة الحجر المستخدمة في ماليزيا

كسارات الحجر mpumalanga

قضية مقاطعة الحجر

الفحم محطم applicatin

آلة قطع الحجر التعدين المصنوعة في الصين

سفينة ناقلة الفحم ويدرون رمل فارك السيليكا

صناعة الأسمنت باكستان

عملية الإنتاج هيكل الإطار مربع الكسارة الهيدروليكية

آلة كسارة الصخور الصلبة 200tph السعر

جديد فاصل المغناطيسي المنتجة

كسارة ساخنة للبازلت جاكرتا؟

آلة منجم الذهب لسحق الجدار

‘إنجاز نشاطات احتراق بعض المواد الصلبة و السائلة

كسارة رزلا في دلهي

محجر الطين السيراميك للبيع

dragon rahang crusher

حول لدينا

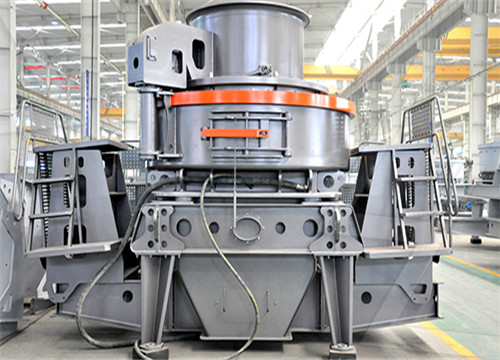

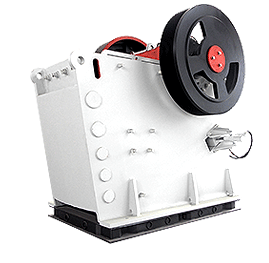

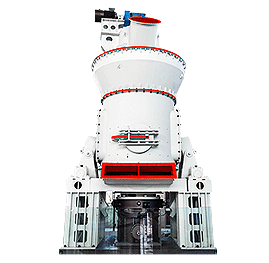

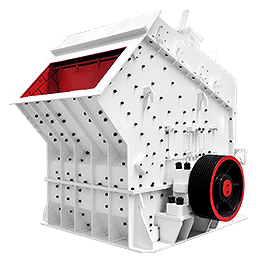

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20