الحار منتجات

ملكنا الإخبارية

processing nickel processing

The Comprehensive Guide to Nickel Processing

2024/1/19 Nickel processing is a complex and multi-stage procedure that involves various techniques to extract, refine, and transform the metal into valuable products. This guide has provided an overview of the nickel

获取价格

Nickel processing Extraction Refining Techniques

nickel. nickel processing, preparation of the metal for use in various products. Although it is best known for its use in coinage, nickel (Ni) has become much more important for its many industrial applications, which owe their importance

获取价格

Nickel industry - Part 1 - Processing nickel laterites and

2024/5/3 Two broad ore types. Nickel occurs in two broad ore types: laterite (oxide) ores, principally located in tropical and sub-tropical areas, and. sulfide ores, principally located in the temperate to sub-Arctic regions. Major

获取价格

Nickel Mining and Processing General Kinematics

2014/4/10 Nickel matte remains after the mining and processing of either lateritic or sulfidic ore. Using the fluid bed roasting procedure, a 95 percent pure nickel can be achieved after additional refinement. Electric cells provide for a

获取价格

Nickel industry - Part 2 - Processing nickel laterites and smelting

2024/8/7 Laterites make up over 70 % of both nickel production and known terrestrial resources today and have been the fastest growing source of nickel for some time. In Part 2 of

获取价格

(PDF) Advanced Review on Extraction of Nickel from

2019/1/10 summarized. Nickel extraction from primary resources such as ores/minerals (sulfides, arsenides, silicates, and oxides) including the unconventional one viz., the polymetallic sea nodules, and ...

获取价格

Hydrometallurgical nickel and cobalt plants and processes

The leaching process results in an aqueous nickel and/or cobalt sulfate solution. This solution is further treated through iron, manganese, and other impurity-removal and solvent-extraction

获取价格

Nickel laterite processing and electrowinning practice

2002/8/1 Nickel laterite processing and electrowinning practice. Nickel as cathodes, rounds, powders, and salts, is recognized as a useful substance in heavy industry. Today, only

获取价格

Recent Progress in Hydrometallurgical Processing of Nickel

2022/8/22 Nickel: Market Outlook to 2018, Roskill, London, 2014. Stopić SR, Friedrich BG, Hydrometallurgical processing of nickel lateritic ores, Vojnotehnički glasnik/Military

获取价格

Processing of low-grade ultramafic nickel ores: A critical review

2024/11/1 In addition, the systemic exploration of nickel sulfide ores has led to resources that are more challenging to process due to the higher impurities. The processing complexity necessitates the development of new technologies and pathways to sustainably process globally abundant low-grade Ni sulphide ores.

获取价格

Copper-Nickel Ore Processing - 911Metallurgist

2019/11/7 The separation of copper from nickel is based on the fact that there is an appreciable difference in the pH at which the two metals are extracted. Copper can be extracted, with very small amounts of nickel, at pH 6.0 to 6.5, while nickel is extracted from the copper raffinate at pH 8.0 to 8.2.

获取价格

(PDF) Advanced Review on Extraction of Nickel from

2019/1/10 Processing options for various types of nickel ore and their products (Adapted from Crundwell et al., 2011). High-pressure acid leaching (HPAL) process flowsheet operating at Moa Bay (Adapted from ...

获取价格

Philippines: Ore-to-Nickel and Cobalt Processing Facility

The proposed facility would recover nickel through extractive processing and use approximately 600,000 MT of EMI’s mine production to produce 20,000 MT of mixed hydroxide precipitate (“MHP”) annually for sale as battery precursor materials. In addition to MHP, the plant could produce other higher-value products, such as magnetite, cobalt ...

获取价格

Processing of Arsenic-Containing Manitoba Nickel Concentrate

Vale Base Metals has operated the Long Harbour Processing Plant (LHPP) since 2014. The hydrometallurgical process facility includes a concentrate re-grind circuit, pressure oxidation autoclaves, neutralization and impurity removal circuits, and electrowinning to recover nickel, cobalt, and copper metals.

获取价格

Ultrafast melting, spallation, and phase explosion in femtosecond

Phase change plays an essential role in femtosecond laser micro/nano-processing in metals, ... [39], and nickel-based alloys [33], as well as phase explosion in Au [14], Al [37], [39], and steel [35], [39] were experimentally observed by pump–probe transient reflectivity microscopy. In these reported cases, the observed reflectivity mappings ...

获取价格

Recent Progress in Hydrometallurgical Processing of Nickel

2022/8/22 Norgate T Jahanshahi S, Assessing the energy and greenhouse gas footprints of nickel laterite processing, Minerals Engineering, no. 7, 24 (2011) 698-707. Article Google Scholar Rhamdhani MA, Chen J, Hidayat T, Jak E Hayes P, Advances in research on nickel production through the Caron process, Proceedings of EMC, (2009).

获取价格

Review on comprehensive utilization of nickel laterite ore

2024/11/1 This process achieves a short process recycling of nickel–iron, Yuan et al.(2020) obtained a deeply reduced product under conditions of a reduction temperature of 1275°C, reduction time of 50 min, and a carbon coefficient of 2.5, after magnetic separation they obtained nickel–iron concentrate with a nickel grade of 6.96 % and iron grade of ...

获取价格

Challenges in processing nickel laterite ores by flotation

2016/6/10 Thus, the challenge of processing nickel laterite ores still exists. In fact, no physical separation technique (including flotation) has been able to dramatically upgrade nickel in laterite ores (Quast et al., 2015a). The only isolated case with an acceptable nickel upgrading is the result by Denysschen and Wagner (2009). They used dense medium ...

获取价格

Efficient extraction of nickel from chloride system using a cleaner ...

2024/8/15 The efficient recovery of nickel from chloride systems has long presented a challenge in the field. While solvent extraction is a viable approach, conventional extractants have been associated with drawbacks such as a high requirement for chloride ions and substantial consumption of acids and alkalis. In response to these challenges, this investigation

获取价格

Processing of oxidized nickel ores using sintering, roasting and ...

2022/5/15 A similar process has been developed in the processing of oxidized copper ores; more than 500 million tons/year are processed using this method (Ghorbani et al., 2015, Khalezov et al., 2019, Kolmachikhina et al., 2019). The possibility of using this technology for nickel-containing ores is very attractive, since the ore is processed near the ...

获取价格

Nickel laterite processing technologies – where to next?

2010/5/27 In the processing of nickel laterite ore into metal, it can be processed by pyrometallurgy method that typically use coal as a reductant. However, coal is a non-renewable energy and have high ...

获取价格

Nickel Ore Processing, Nickel Alloy Metallurgy, Training Courses

Electrical Motors; Electrical Transformers; Generators; Industrial Automation Drives; Electrical Circuits; Control Valves; Measurement devices; Analysers Specialist

获取价格

Nickel Ore Processing Plant - JXSC Mineral

It often uses a stage grinding process when processing nickel ore. The crushed products enter the ball mill for a stage of grinding and then enter the spiral classifier for pre-classification. If the ore particle size of nickel ore is too coarse (greater than 0.1mm) or too fine (less than 0.006mm), it is unfavorable for the subsequent flotation

获取价格

Processing of oxidized nickel ores using sintering, roasting and ...

2022/5/15 A similar process has been developed in the processing of oxidized copper ores; more than 500 million tons/year are processed using this method (Ghorbani et al., 2015, Khalezov et al., 2019, Kolmachikhina et al., 2019). The possibility of using this technology for nickel-containing ores is very attractive, since the ore is processed near the ...

获取价格

Nickel laterite processing technologies – where to next?

2010/5/27 In the processing of nickel laterite ore into metal, it can be processed by pyrometallurgy method that typically use coal as a reductant. However, coal is a non-renewable energy and have high ...

获取价格

Nickel Ore Processing, Nickel Alloy Metallurgy, Training Courses

Electrical Motors; Electrical Transformers; Generators; Industrial Automation Drives; Electrical Circuits; Control Valves; Measurement devices; Analysers Specialist

获取价格

Nickel Ore Processing Plant - JXSC Mineral

It often uses a stage grinding process when processing nickel ore. The crushed products enter the ball mill for a stage of grinding and then enter the spiral classifier for pre-classification. If the ore particle size of nickel ore is too coarse (greater than 0.1mm) or too fine (less than 0.006mm), it is unfavorable for the subsequent flotation

获取价格

Long Harbour Nickel Processing Plant - Alchetron

2024/9/21 The Long Harbour Nickel Processing Plant is a Canadian nickel concentrate processing facility located in Long Harbour, Newfoundland and Labrador. Operated by Vale Limited, construction on the plant started in April 2009 and operations began in 2014. Construction costs were in excess of CAD 4.25 bil

获取价格

Philippines eyes boost to nickel processing capacity - AOL

2024/5/10 Processing its nickel ore output would be the ideal scenario for the Philippines, said Economic Planning Secretary Arsenio Balisacan, and the time was right as its seeks to add value to its ...

获取价格

Nickel Ore Mining, Beneficiation, and Processing: A

Tuxingsun Mineral Mining provides comprehensive solutions for nickel mining, beneficiation, and processing. We offer a wide range of services, from exploration and mine development to mineral processing and refining. Our experienced team utilizes cutting-edge technologies and equipment to deliver high-quality results for our clients.

获取价格

Nickel Processing Equipment, Process Flow, Cases - JXSC Machine

2019/8/26 Nickel sulfide deposits contain the remaining forty percent (56 million tons). Demand for nickel in the United States is much higher than what recycled nickel can provide, so nickel is imported into the country. Most of the imported nickel comes from Canada, 34%; Russia, 16%; Australia, 11%; Norway, 10%; and other countries, 29%.

获取价格

Research Status and Prospect of Ultrasonic Vibration and

2024/1/19 ABSTRACT: Nickel-based alloys has important application value in modern industrial field, but there are a lot of problems that are difficult to solve in traditional processing, and it is a typical difficult-to-process material. In order to improve the machinability of nickel-based alloys, scholars try to use a variety of non-traditional processing methods to explore and study

获取价格

Hydrothermal processing of nickel containing biomining or ...

2001/7/1 Experimental conditions of the nickel/biomass solution conversion experiments were as follows: Pump A introduces a nickel/biomass model solution to the reactor at a flow rate of 1.5 ml min −1.Pump B feeds either pure water, or a solution of formic acid to the preheater held at 450°C at a flow rate of 5 ml min −1.In the preheater, the formic acid decomposes into CO 2,

获取价格

Nickel laterite processing and electrowinning practice

The state-of-the-art review regarding nickel processing methodologies provides alternate approaches for greenfield sites or plant retrofits in situ. 6. Conclusions and recommendations • Electrowinning operations are important when recovering associated by-products of nickel production such as copper, cobalt, and zinc from pressure leach ...

获取价格

THE DNi PROCESS™ - Altilium Group

The DNi Al Process™ is capable of processing bauxite and/or red mud, which can be rich in rare earth elements (REEs) and other valuable metals. This breakthrough process reduces the need for new mines, mitigates environmental hazards, and addresses existing waste challenges. Its ability to eliminate red mud production signifies a monumental ...

获取价格

Processing of nickel aluminides and their industrial applications

1992/1/1 Chemical processing Nickel aluminides offer a favorable combination of strength and corrosion resistance for use as extruder stems for the processing of artificial rubber. This application requires the hot workable alloy, ease of machining and grinding. Alloy IC-218LZr will be used for this application.

获取价格

Long Harbour Nickel Processing Plant Kiewit Corporation

Long Harbour Nickel Processing Plant Long Harbour, Newfoundland. Located on the island of Newfoundland, Long Harbour Processing Plant is one of the largest in the world to use a hydrometallurgical process that refines 50,000 tons per year of nickel ore. KBAC Constructors, a partnership between Kiewit, BMA Constructors and GJ Cahill, installed ...

获取价格تستخدم اليابان آلة طحن الحجر

صبخي نبهان صناعة النحاس

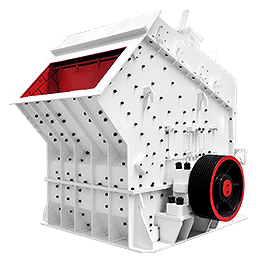

معدات التعدين كسارة ايطاليا

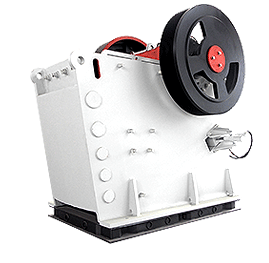

تخطيط الفني لكسارة الفك

600TPH Rock Crusher

آلة كسارة الرخام عالية الكفاءةكسارة مخروطية لخط إنتاج الحجر

شنغهاي تغذية كسارة المتجددة

نشرت كسارة الفك

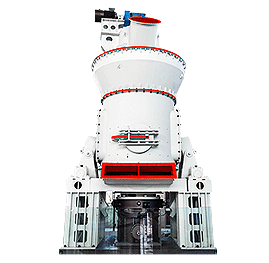

الرأسي مطحنة loesche الصين

عالية السعة خام الجرانيت الحجر الجيري كسارة الفك الصخور pe 250x400

الرسم مطحنة في ألمانيا

كسارة الفك الصغيرة pe150x250 لعملاء زيمبابوي

الذهب تشغيل المصنع غسل التعدين للبيع

بطری پت تولید کننده دستگاه خرد در هند

مطحنة زيت النخيل 60mt ساعة

ساياجي كسارة ألوغو

لآلة سحق الشراكة المتاحة في الهند

الحصى الجدول جبل سحقت

مصنع لتجهيز المورد في السعودية جزيره العرب

آلة تكسير الخردة جنوب إفريقيا 6 المعدات اللازمة للمحاجر

possible names for a mining company

تكلفة إنتاج الحصى

مجموعة بناء الرمل والطوب أذربيجان

تكلفة إنشاء الاسمنت مصنع

جعل مصر الشاشة تهتز الفحم

توجه فک سنگ شکن

حول لدينا

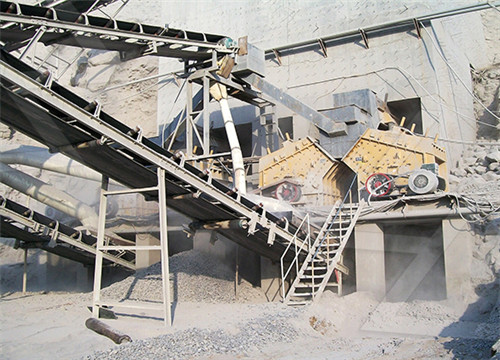

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20