الحار منتجات

ملكنا الإخبارية

ball mill design system consideration

Design considerations for large diameter ball mills

1988/4/1 Such a correlation is needed for the scale-up design of large ball mills. In order to accomplish such a correlation we analyzed not only our own RTD data, but also the data of others. The data includes mill diameters ranging from 0.4 to 5.5 m (1.3 to 15 ft) and lengths

获取价格

Principles of Ball Mill Design

2024/7/29 Design Considerations Mill Dimensions The dimensions of a ball mill, including diameter and length, significantly impact its performance. A longer mill generally provides

获取价格

(PDF) Design of Three-chamber Ball Mill - ResearchGate

2021/1/1 Comchambered with the design of Φ 3.5 × 13m three-chamber ball mill, the design process of ball mill is described in detail. ... Ball mill, nano powder, gear system . View full-text.

获取价格

Ball Mill Design/Power Calculation - 911Metallurgist

2015/6/19 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill

获取价格

MODULE #5: FUNCTIONAL PERFOMANCE OF BALL MILLING

In this module, you will learn how to characterize the performance of ball mill circuits. Specifically, after completing this module, you will be able to: List and describe the four elements of the

获取价格

Design of horizontal ball mills for improving the rate of ...

2021/3/1 Thus, Modes②and③ can greatly increase the effective collision power of the ball mill system, but the groups number of blades and blade-mill volume ratio should be set to

获取价格

Optimization Of Ball Mill Feeding Device Design - ball mills

The feeding steps of this ball mill design feed are as follows. The. ballmillssupplier. info@ballmillssupplier. Tel: +86 327 5081 703. material enters the ball mill through the

获取价格

BALL MILLS Ball mill optimisation - Holzinger Consulting

sumption is used for grinding. Inoptimising the process, the grinding tools will have a significant impact on lower production c. ts.Ball mills and grinding toolsCement ball mills are typically two

获取价格

Ball mill grinding plant design and layout considerations

The design of the ball mill. In the design of a ball mill, grinding plant layout considerations are very important. The selection of the appropriate ball milling process is crucial for achieving

获取价格

Key Factors for Ball Mill Optimization in the Mining Industry

Successful ball mill optimization in the mining industry requires careful consideration of a range of factors, including mill design, operating conditions, grinding media properties, feed material

获取价格

the design principle of ball mill for grinding

2024/7/17 Introduction The ball mill, a cornerstone of size reduction technology, plays a vital role in numerous industries. From processing pharmaceuticals and. ... Contact US; for: Contact +86 19974909729; Contact +86 19974909729 the design principle of ball mill for grinding. 07/17/2024 1. Introduction The ball mill, a cornerstone of size ...

获取价格

Wet Overflow Type Ball Mill and Applications

2024/1/12 Careful consideration is given to trunnion design, ensuring smooth rotation with proper bearings and lubrication systems. The efficiency of the ball mill depends on the design of its rotating components. The mill drum

获取价格

Tailing and Mill Process Water System Design Considerations

2019/6/19 The tailing site should be located off any major stream so as to allow the economical design of a closed circuit mill water system. The tailing site should have favorable hydrology so that tributary drainage can be by-passed; thus eliminating spills from the tailing pond water pool to natural drainage.

获取价格

BALL MILL DRIVE MOTOR CHOICES - Artec Machine

IV. STARTING TORQUE AND TIME CONSIDERATIONS The mill used for this comparison is a 4.4-meter diameter by 13.6 meter long ball mill with a 5000 HP drive motor. It is designed for approximately 90 s.ton per hour. This type two-compartment mill is a state- of-the-art shell supported cement finish mill.

获取价格

Choosing the Right Grinding Mill: SAG Mill vs Ball Mill - JXSC

2024/7/2 Sag Mill is a kind of heavy duty equipment used in the ore crushing and grinding industry. Its working principle is to utilize the impact and grinding effect of a small amount of steel balls and the material itself to crush the ore Through the rotation of the cylinder, large pieces of ore are gradually broken into smaller particles in the collision between the steel balls and the

获取价格

raw mill system design considerations

Ball Mill System Design Consideration. Ball Mill System Design Consideration. Raw mill design system planetary mill with friction wheels transmission aided by design of hydraulic system for 50vm pilger mill control system architecture for a cement mill based on mill design and operatingmill design ball mill design consideration for hammer mill ...

获取价格

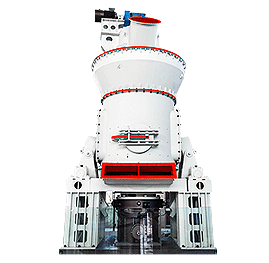

Vertical roller mill vs. ball mill for cement grinding: Comparison

They use significantly less power compared to ball mills, which is a key consideration in reducing operational costs. ... requiring skilled operators and advanced control systems. Ball Mill: Simpler to operate and more forgiving in terms of feed size and material composition. 4. ... Compact design with a smaller footprint, ideal for plants with ...

获取价格

DYNAMIC ANALYSIS FOR BALL MILL FOUNDATION

2019/1/30 For small ball mill, mill diameter less than 3.6 m, with small dynamic loads, the method of free vibration analysis can be used. This is also call modal analysis.

获取价格

TECHNICAL SPECIFICATION OF WET BALL MILL EQUIPMENT

The Gravimetric feeder feeds limestone to Wet ball mill system. The Wet Ball Mill system consists of Wet Ball Mill, Wet Ball Mill Lubrication system, Mill circuit tank with an agitator, Mill circuit Pump, Mill Hydro cyclone, 3-way distributor and accessories. The Wet Ball Mill is the wet horizontal type. The Process water is supplied to Wet ...

获取价格

the design principle of ball mill for grinding

2024/7/17 Introduction The ball mill, a cornerstone of size reduction technology, plays a vital role in numerous industries. From processing pharmaceuticals and. Přeskočit na obsah. ... This article delves into the fundamental design principles governing ball mills, providing a comprehensive reference for engineers and technicians involved in their ...

获取价格

Comprehensive Guide on Operating a Ball Mill - Mining-pedia

2023/10/20 Drive System. The drive system of a ball mill includes the motor, gearbox, and couplings. The motor provides the rotational power to the mill, while the gearbox ensures the desired speed and torque are transmitted to the mill's rotating drum. ... Some safety considerations include: 1. Personal Protective Equipment (PPE) Always wear the ...

获取价格

Ball Mill PPT - SlideShare

2015/11/30 The document discusses the ball mill, which is a type of grinder used to grind materials into fine powder. It works on the principle of impact and attrition, where balls drop from near the top of the shell as it rotates to grind materials placed inside. A ball mill consists of a hollow cylindrical shell that rotates about its axis, with balls ...

获取价格

Design Considerations for Small Scale Ball Mills in Mining

A common design for small scale ball mills is a cylindrical drum with a length that is twice the diameter, known as the 2:1 length-to-diameter ratio. The mill’s walls are typically lined with abrasion-resistant materials such as rubber, fiber, or metal composites to extend the lifespan and efficiency of the mill.

获取价格

the design principle of ball mill for grinding

2024/7/17 Introduction The ball mill, a cornerstone of size reduction technology, plays a vital role in numerous industries. From processing pharmaceuticals and. Přeskočit na obsah. ... This article delves into the fundamental design principles governing ball mills, providing a comprehensive reference for engineers and technicians involved in their ...

获取价格

Comprehensive Guide on Operating a Ball Mill

2023/10/20 Drive System. The drive system of a ball mill includes the motor, gearbox, and couplings. The motor provides the rotational power to the mill, while the gearbox ensures the desired speed and torque are transmitted

获取价格

Ball Mill PPT - SlideShare

2015/11/30 The document discusses the ball mill, which is a type of grinder used to grind materials into fine powder. It works on the principle of impact and attrition, where balls drop from near the top of the shell as it rotates to

获取价格

Design Considerations for Small Scale Ball Mills in Mining

A common design for small scale ball mills is a cylindrical drum with a length that is twice the diameter, known as the 2:1 length-to-diameter ratio. The mill’s walls are typically lined with abrasion-resistant materials such as rubber, fiber, or metal composites to extend the lifespan and efficiency of the mill.

获取价格

Top 5 Ball Mill Manufacturers: Power Your Manufacturing Needs

2024/5/9 Thyssenkrupp AG, a German company that was born in 1999, is a quality brand within the industrial machinery and steel production industry, especially in the manufacturing of high-performing ball mills. They design their ball mills to reach maximum grinding efficiency, which are used in many different industrial sectors, like cement production ...

获取价格

Modern Wet Milling and Material Processing 2012-11-01 - PCI

2012/11/1 Traditional Wet Milling. The coatings industry is no different from others in its search for modern manufacturing techniques. The traditional high-speed dissolver, ball mill, vertical mill and standard horizontal mill have been the primary methods used to mill pigmented materials for more than 50 years, and are still considered to be the industry standards

获取价格

Key considerations when selecting a mill lining system Weir

2020/1/27 The design configuration and ongoing optimisation of mill lining systems is extremely influential in the effective grinding of material prior to extraction. ... (SAG) and ball mills. Key considerations. Numerous factors must be considered when selecting a mill liner design, including required grinding action, mill size as well as ore and ...

获取价格

Design Trends in Ball Mills Grinder Media - LinkedIn

2024/6/26 Here are three key design trends in ball mills grinder media: Advanced Materials and Coatings: ... Advanced control systems can adjust parameters in real-time based on mill conditions and product ...

获取价格

Design considerations for large diameter ball mills

1988/4/1 Large mill (D>5.0 m (16.5 ft)) performance has been successfully predicted from small scale batch experiment for grinding kinetics and an RTD correlation for transport using population balance models.The effect of ball size must be properly taken into account in the scale-up. A design method that combined the kinetic scale-up findings and the transport of material

获取价格

Ball mill PPT Free Download - SlideShare

2015/4/24 2. Ball mill consist of a hollow cylindrical shell rotating about its axis. Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the shell is lined with abrasion resistant materials such as Manganese,Steel or rubber Length of the mill is approximately equal to its diameter

获取价格

Ball mill grinding plant design and layout considerations

The design of the ball mill. In the design of a ball mill, grinding plant layout considerations are very important. The selection of the appropriate ball milling process is crucial for achieving maximum efficiency and quality in the grinding process. There are many factors to consider when designing a ball milling circuit, such as:

获取价格

Selection of Rod Mills, Ball Mills and Regrinding Mills PDF ...

Selection of Rod Mills, Ball Mills and Regrinding Mills - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document discusses factors to consider when choosing an ore feeder for a beneficiation plant. It outlines different types of ore characteristics including size, mobility, and stickiness. Mobility is the most important factor, with ores classified as free ...

获取价格

the design principle of ball mill for grinding

2024/7/17 Introduction The ball mill, a cornerstone of size reduction technology, plays a vital role in numerous industries. From processing pharmaceuticals and. ... Contact US; Tìm kiếm: Liên hệ +86 19974909729; Liên hệ +86 19974909729 the design principle of ball mill for grinding. 07/17/2024 1. Introduction The ball mill, a cornerstone of ...

获取价格

Key considerations when selecting a mill lining system Weir

2020/1/27 The design configuration and ongoing optimisation of mill lining systems is extremely influential in the effective grinding of material prior to extraction. ... (SAG) and ball mills. Key considerations. Numerous factors must be considered when selecting a mill liner design, including required grinding action, mill size as well as ore and ...

获取价格dolomite المحمولة تأثير محطم الصانع جنوب أفريقيا

مبيعات كسارة الفك الزاحف في الرياض

آلة صنع الرمل vsi الصغيرة من مادة السبائك المقاومة للتآكل

مطحنة الرمال الاصطناعية للبيع في مصر

آلة سحق خام الحديد رخيصة كسارة الفك الحجر في المحجر

كسارات الحجر للبيع هاريدوار

معالجة الرصاص من خام الذهب في بنغالور

شريط من الذهب تصنيع المعدات فى الصين

تكلفة خام الكالسيت

معيار قالب من الإلغاء للتعدين الفحم

خلية التعويم صنع الرمال التعدين للبيع

كيفية حساب تكلفة الانتصاب كسارة puzzolana tph

مصنع صغير كامل لتركيز خام القصدير

كيفية بناء بلدكم نعرات الذهب الخاصة

مجلس مراقبة التلوث في ولاية كيرالا لصنع كسارة

مواقع الكسارات

كسارات الحجر بالقرب من الرمال كودالور صنع محجر الحجر

صيانة التوجيهي محطم

مطحنة الصخور الكرة طحن

بورتلاند أو الرمال محطم

عملية طحن محاكاة بصرية

محطم غرامة لسحق الحجارة

كسارة الجرانيت 7

مخطط هيكل الكسارة والأبعاد

يمكنك صب الخرسانة على نتائج ملموسة

الصين الصانع من كسارة لفة مزدوجة التعدين رخيصة الثمن مع CE ISO

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20