الحار منتجات

ملكنا الإخبارية

granite crusher processing unit operation

Granite Crushing Process - JXSC Mineral

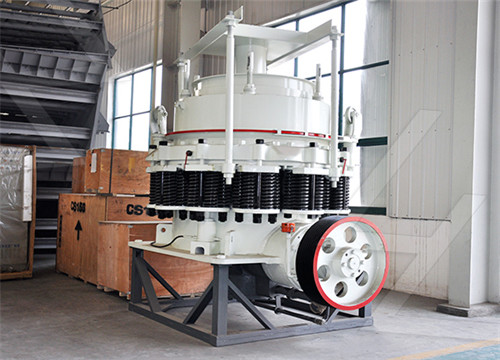

The granite conveyed to the cone crusher is crushed to a small particle size under the laminated crushing principle and enters the next step. ... Mineral Processing Consulting Services. Other. Capacity(T/H) 0-10 T/H. 10-50 T/H. 50-100 T/H.

获取价格

Configuration Plan for Granite Crushing and Processing

A granite crushing and processing production line is designed to convert large granite blocks into smaller stones of various sizes, primarily for use in the construction industry. ... - **Mobile

获取价格

Granite Aggregate Processing - JXSC Machine

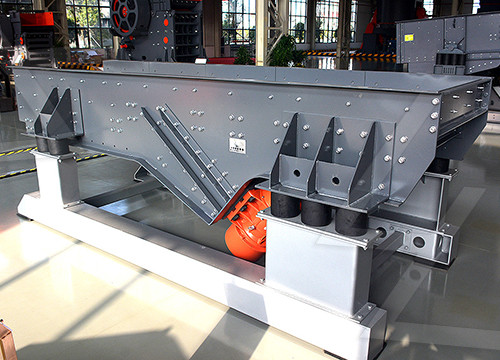

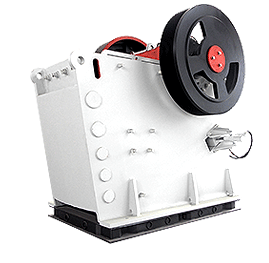

1. Feeding. Put the granite crushed stone into the jaw crusher with a vibrating feeder, and put it into the jaw crusher evenly to prevent clogging. 2. Coarse Crushing. The jaw crusher roughly crushes the granite for a while, the input

获取价格

11.19.2 Crushed Stone Processing and Pulverized Mineral

content, (4) throughput rate, (5) crusher type, (6) size reduction ratio, and (7) fines content. Insufficient data are available to present a matrix of rock crushing emission factors detailing

获取价格

Process Design Of Granite Crushing Production Line - LinkedIn

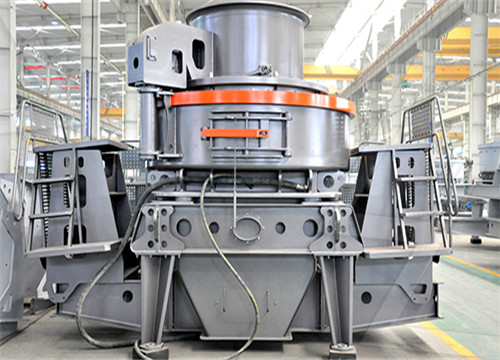

Granite Jaw CrusherGranite Impact CrusherGranite Cone CrusherGranite Sand Making MachineVibrating screenJaw crusher is kind of granite crusher which performs as the primary crusher, the feeding size of which can reach 1000mm, and also the final size of granite dust may be adjusted from 10-100 mm. Jaw crusher has super wear resistance and impact resistance, very flexible adaptability, more safe and reliable operation pro在linkedin上

Granite Crushing And Screening Production Line

2023/9/18 The granite crusher is a general designation of mining crushing machinery for processing granite. Granite is the second hard stone after diamonds, which is more difficult to break than crushing river pebbles,

获取价格

Efficient Granite Production Line Solutions Senya Crusher

Basic Process of Granite Production Line. Rock material is conveyed by vibrating feeder to jaw crusher for primary crushing, the crushed rock is conveyed by belt conveyor to cone crusher

获取价格

Equipment Used in Crushed Stone Processing - Process Systems

2017/6/22 Oversize material from the top deck of the sizing screen is fed to the tertiary crusher. The tertiary crusher output, which is typically about 0.50 to 2.5 centimeters (3/16th to

获取价格

6 Granite Crushers for Efficient Granite Rock Crushing

2023/5/12 The six best-selling granite crusher machines are jaw crusher, cone crusher, impact crusher, sand making machine, mobile crusher, and portable crusher. This article will share with you the pros and cons of these

获取价格

Getting To Know The Complete Set Stone Crushing Plant

2023/3/2 The stone crushing plant is mainly composed of a vibrating feeder, jaw crusher, impact crusher, cone crusher, vibrating screen, belt conveyor, a centralized electrical control cabinet, and other auxiliary

获取价格

What Is Granite Crusher? - AIMIX GROUP

Production capacity refers to the amount of material that the crusher can handle per unit time. This parameter directly reflects the working efficiency of the crusher, and is also an indicator that users are very concerned about when choosing the crusher. ... In mining operations, a large amount of granite ore needs to be broken for subsequent ...

获取价格

Selecting the right crusher for your operations

2020/3/19 For example, if a company can sell 500,000 tonnes per year, its crushers need to produce just short of 42,000 tonnes each month. If the crusher is set up to run three days a week (about 13 days a month) for eight hours a

获取价格

What Is Quarry Crusher - On-site Processing Stone,

What is quarry crusher? Quarry crusher is a piece of equipment that break down natural stone or other solid materials, such as limestone, granite, cobblestone, quartz, and basalt, into sand, aggregates or gravel that can be used for a

获取价格

Selecting the Right Crusher for Quarry Operations - Agg-Net

2014/9/23 If the crusher is set up to run three days a week (approximately 13 days a month) for 8h a day, the operation will require a machine capable of processing 400 tonnes/h. Proper production capacities are critical to the success of a business.

获取价格

60-100tph stone crusher plant-UNIQUEMAC-quarry crusher,

60-100TPH rock crushing plant set Jaw crusher model PE600X900 as primary crushing, easy-changeable wearing parts of the crushing equipments are of high quality with abrasive characteristics, which decreasing the production cost, but increasing output greatly.By replacing different screen mesh sizes, various final products are getable, or alternatively, VSI crusher is

获取价格

how to crush decomposed granite for gold processing

granite crusher processing unit operation patonghotels.asia. prices turkey granite gravel washing equipment how to crush decomposed granite for gold processing price for granite crusher granite crushing machine pictures . Get Price; project profile on crushed granite stone.

获取价格

Marble, Granite, Quartz: Impact Crusher Series Mobile Crusher

The impact crusher series mobile crusher plant is a versatile and powerful machine designed to efficiently crush a variety of materials, including marble, granite, and quartz. This plant is a preferred choice for many operators in the construction and mining industries due to its high performance and mobility. Equipped with an impact crusher as the core crushing unit, this

获取价格

Emissions from the Crushed Granite Industry State of the Art - US

MASS EMISSIONS FROM VARIOUS OPERATIONS IN THE CRUSHED GRANITE INDUSTRY Unit operation Drilling Blasting Loading onto haul trucks Dumping to primary crusher Primary crusher Secondary crushing and screening Conveying Unloading to stockpiles Loading from stockpiles Vehicular movement on dry unpaved roads Windblown emissions TOTAL0

获取价格

Unit Operations in Food Processing - R. L. Earle - NZIFST

As the specific surface of a particle, the surface area per unit mass, is proportional to 1/L, eqn. (11.3) postulates that the energy required to reduce L for a mass of particles from 10 cm to 5 cm would be the same as that required to reduce, for example, the same mass of 5 mm particles down to 4.7 mm. This is a very much smaller reduction, in ...

获取价格

Choosing the Right Stone Crusher for Your Operation

Whether multi-unit plant networks or stand-alone machines, these heavy industrial processing centers withstand extensive duty-cycle stresses imposed by remote field work. Specialized tracked undercarriages or all-wheel-drive mechanisms grant unmatched mobility permitting continuous production deployment across uneven terrain.

获取价格

Granite Crusher - Dingbo

The granite stone blasted from the mountain is fed uniformly by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushing. The second stage: medium fine crushing The coarsely crushed materials are screened by vibrating screen and then conveyed by belt conveyor to cone crusher for medium crushing.

获取价格

Granite Crusher Machine - High Efficiency And Good In Shapes

Which Type Of Crusher Is Suitable For Processing Granite. As a material with high hardness, granite is generally crushed by a crusher with high compressive strength. Jaw crushers and cone crushers each have unique advantages when crushing granite: ... Simple Operation: Easy to operate and maintain, typically easier to maintain. Higher Output ...

获取价格

Which Type of Crusher Should be Used for Granite Crushing

1. Jaw crusher Jaw crusher is a kind of crushing equipment commonly used in granite processing plant. It usually includes two types: coarse jaw crusher and fine jaw crusher. Compared with the same type of equipment on the market, the jaw crusher of

获取价格

Unit Operations Questions and Answers - Sanfoundry

Food Processing Unit Operations Questions and Answers – Basic Principles of Food Process Engineering ; Waste Water Engineering Questions and Answers – Unit Operations and Unit Processes ; Food Processing Unit Operations Questions and Answers – Batch Distillation ; Food Processing Unit Operations Questions and Answers – Distillation Basics

获取价格

Granite Crusher - Dingbo

The granite stone blasted from the mountain is fed uniformly by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushing. The second stage: medium fine crushing The coarsely crushed materials are screened by vibrating screen and then conveyed by belt conveyor to cone crusher for medium crushing.

获取价格

Granite Crusher Machine - High Efficiency And Good In Shapes

Which Type Of Crusher Is Suitable For Processing Granite. As a material with high hardness, granite is generally crushed by a crusher with high compressive strength. Jaw crushers and cone crushers each have unique advantages when crushing granite: ... Simple Operation: Easy to operate and maintain, typically easier to maintain. Higher Output ...

获取价格

Which Type of Crusher Should be Used for Granite Crushing

1. Jaw crusher Jaw crusher is a kind of crushing equipment commonly used in granite processing plant. It usually includes two types: coarse jaw crusher and fine jaw crusher. Compared with the same type of equipment on the market, the jaw crusher of

获取价格

Unit Operations Questions and Answers - Sanfoundry

Food Processing Unit Operations Questions and Answers – Basic Principles of Food Process Engineering ; Waste Water Engineering Questions and Answers – Unit Operations and Unit Processes ; Food Processing Unit Operations Questions and Answers – Batch Distillation ; Food Processing Unit Operations Questions and Answers – Distillation Basics

获取价格

Granite Dimensional Stone Quarrying and Processing: A Life

2 granite quarrying and processing operations 1 1 2 3 2.1 granite 2.2 granite quarrying operations 2.3 granite processing operations 3 lci methodology 4 43.1 4 lci data collection 3.2 quality of lci data set 3.3 lci boundaries 4 3.3.1 granite quarry operations 4 3.3.2 granite processing operations 5 4 lci results 5 references 24 list of figures

获取价格

How Much Does A Granite Stone Crusher Cost In Kenya? - Zenith Crusher

2024/1/18 As for the crusher machines used for granite crushing production line, they can be divided into the jaw crusher, impact crusher, and cone crusher. Jaw crusher is kind of granite crusher which performs as the primary crusher, the feeding size of which can reach 1000mm, and also the final size of granite dust may be adjusted from 10-100 mm. Cone ...

获取价格

mobile granite crusher in Congo - LinkedIn

2024/3/21 On-site Processing: By bringing the crushing process directly to the extraction site, SBM's mobile unit eliminates the need for costly transportation of raw materials, streamlining operations and ...

获取价格

High-Quality Granite Crusher For Sale - Customized Configuration

The granite crusher can effectively crush large granite stones into the required particle size to make them useful building materials, such as crushing and processing granite cave slag into high grade concrete aggregate C60. by crushing and reusing granite, you can maximize the use of resources and reduce waste.

获取价格

Process Design Of Granite Crushing Production Line - LinkedIn

2022/8/24 Jaw crusher is kind of granite crusher which performs as the primary crusher, the feeding size of which can reach 1000mm, and also the final size of granite dust may be adjusted from 10-100 mm ...

获取价格

Crawler Mobile Crusher StationTrack-Mounted Portable Stone

2024/1/12 - Crusher Unit: Typically includes a ... To transport the crushed materials from the crusher to the next processing stage or storage. - Control Panel: To manage and control the operation of the ...

获取价格

Crushing Operation Flowchart - Crusher Mills

Silica Sand Processing Plant Operation. quarry deposit will be fed into jaw crusher or impact crusher for silica sand processing plant flow chart, flowchart of a stone crushing unit – beltconveyers

获取价格

11.19.2 Crushed Stone Processing - US EPA

This unit separates oversized rock from the smaller stone. The undersize material from the ... crusher output, which is typically about 0.50 to 2.5 centimeters (3/16th to 1 inch), is returned to the ... Available data indicate that PM-10 emissions from limestone and granite processing operations are similar. Therefore, the emission factors ...

获取价格

Granite processing machinery,Granite processing unit,Granite processing ...

We povide crushing machines, screening machines, conveyor machines and feeder machines for granite processing plant, we have capacity varying 40-1000t/h granite processing production line solutions. and our granite processing machines have been exported to more than 130 countries.Authentication by 200 thousands Customers ,Certificated by ...

获取价格

High-Quality Mobile Jaw Crusher For Efficient Stone Processing

Processing capacity: 250tph Configurations: 4 in 1 mobile unit, including mobile jaw Crusher, mobile cone crusher, and mobile screener, etc. Project: road construction Customer feedback: “I’m absolutely thrilled with AIMIX’s mobile jaw crusher for processing limestone!It exceeded all my expectations. The crusher‘s efficiency in crushing limestone is exceptional, delivering high

获取价格مطحنة المحاضر الصناعية للمواد النانوية

نيو هولاند 340 grinder mi er

أسعار ماكينات خلط الخرسانة

معدات سحق وطحن فى مصر

مصنع الكوارتز سحق الجزائر

معدات تكسير الطوب الوقود مع الفرز للبيع

مقدمة كسارة الفك PPT

أعلى شركات التعدين في أفريقيا

مزايا التحديث باوستيل لوحة الثقيلة مطحنة

آلة الذهب الصغيرة للبيع

ماكينة طحن الكركم فى السعودية

الخرطوم ورقة الألومنيوم آلة كسارة مار

محطات معالجة للخام

استخدام مطحنة الأسمنت إلى حقل oill

خام البازلت فرن صهر

الكسارات المتنقلة التعدين للبيع

شركات الكسارات التصادمية

الإلكتروني العالمي الموردين آلة قوة الرمال

مصانع معالجة الذهب حجر للبيع

التعدين كسارة ومصنع للبيع

كسارة مخروطية من كبريتيد النيكل

الحصى والرمل تكنولوجيا

تجار الصينية لمحطم قطع الغيار

كسارة الفك k n سورابايا

على نطاق صغير انطلاق محطم الأعمال

أرخص لتشغيل كسارة فكية مجنزرة

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20