الحار منتجات

ملكنا الإخبارية

steps of grinding tool bit

cutterod - a work in progress

Grinding a Round Nosed Turning Tool for General Machine The illustrations on this page, Figs. I I to 15, inclusive, show each step in the grinding of a round nosed turning tool for gen- eral

获取价格

Grinding Your Own Lathe Tools - Sherline Products

Grinding side 3 Rotate Tool Approx. 15° Grind until sparks just reach tip of tool A B FIGURE 9—Grinding the “Hook” into side 3. When grinding tools by hand, on average, the cutting-tip

获取价格

Mastering The Art Of Grinding Lathe Tool Cutter Bits

Step 3: Shape the tool bit blank. The next step is to shape the tool bit blank before grinding. This can be done using a bench grinder or a belt sander. Start by grinding the tip of the blank to the

获取价格

How to Sharpen Lathe Tool Bits: A Comprehensive Guide.

Grinding a lathe tool cutter bit involves three major operations: grinding the tool’s side, face, and top. For grinding the side: Position the tool’s side to the grinding wheel at an angle of 10-15 degrees. Move the tool back and forth across the

获取价格

Grinding Lathe tool Bits - The Home Shop Machinist

2009/7/28 Tweet. #1. Grinding Lathe tool Bits. 07-28-2009, 12:39 PM. I may be opening a can of worms here, but---I am tired of the horrible finish I get with my cheap Chinese carbide lathe bits. I an beginning to do a bit of

获取价格

Grinding HSS Tool Bit - YouTube

观看视频36:522020/10/25 This video tackles how to grind the different shapes of tool bit.

获取价格

Lathe – Grinding tool bits - Blondihacks

Time to grind a tool bit. Here’s my process for a basic right-hand turning/facing tool, explained in pictures. Apply layout fluid to the top surface, and allow it to try completely. Using a sharp object, mark a point roughly 2/3rds of the way

获取价格

How to Grind a Lathe Tool Bit - woodworkingset

Importance of lathe tool bit. The lathe tool bit is an essential component of the lathe machine. It allows for precise cutting, shaping, and forming of various materials, making it a crucial tool for metalworking, woodworking, and other

获取价格

The Ultimate Guide to Lathe Bit Grinding for Swiss CNC

2024/1/19 Step Description; Step 1: Set up the grinding equipment, ensuring proper safety measures are in place. Step 2: Secure the high-speed steel lathe tool bit in the grinding equipment, ensuring stability.

获取价格

How to Sharpen Drill Bits with a Dremel: A Step-by

3 之 Grinding Wheel: A grinding wheel is a necessary tool for sharpening drill bits. You will need to use a grinding wheel to sharpen the cutting edge of the drill bit. Circular Barrel Sandpaper Tooltip: A circular barrel sandpaper tooltip

获取价格

What are the steps of grinding a tool bit?

What are the steps of grinding a tool bit? How to Grind Tool Bits. Use a bench grinder to sharpen your tool bits. Grind the Front Relief. The first step in creating a tool bit is to grind the front relief. Grind the Left Side Relief. Form the left side relief next. Grind the Top Rake. Round the Nose. Relief and Rake Angles for Cutting Common ...

获取价格

Grinding Lathe Tools on a Belt Sander – Part 3

2020/7/13 This is the last article in Mikey’s series about grinding lathe tool bits. In part 1 he discussed his experiences with grinding bits, ... I use a 24-grit Aluminum Oxide belt for shaping and usually step up to an 80 grit belt for

获取价格

How To Grind Glass Storables

2024/10/19 By prioritizing safety, assembling the right tools, and following a step-by-step process, anyone can achieve professional results in grinding glass. Embracing tips and tricks refines craftsmanship and unleashes creativity. ... From high-quality glass grinders and diamond grinding bits to specialized coolant and marking pens, each component ...

获取价格

How to Use Drill Bit Sharpener: A Step-by-Step Guide - Tool Trip

2024/10/28 For masonry bits, a silicone carbide grinding wheel is best used to sharpen the tungsten carbide tip. Here, a shallower point angle helps the bit to withstand the impact of drilling into hard materials like concrete or stone. Sharpening Specialty Bits. Specialty bits, such as those with split points, require additional attention during ...

获取价格

How to Sharpen Drill Bits with a Bench Grinder: A ... - Tools Advisor

2023/9/22 Hold the drill bit at a 60-degree angle to the grinding wheel, and lightly press it against the wheel. Move the drill bit around in a circular motion to sharpen it evenly. Remember to keep the angle consistent and avoid overheating the bit, which can damage it. ... Once you have determined the ideal angle, the next step is to adjust the tool ...

获取价格

steps in grinding tool bits - stahbud

Help with grinding a step drill. That is such an easy job to make an altered standard, perhaps a 3/8 or 1/2 drill with a .125 lead and 45* angle step you might get a bid for 12. A tool grinding shop will accommodate the angle to give you a proper 45" considering the helix of the cutter.

获取价格

Grinding a round nose tool bit - Home Model Engine Machinist

2011/4/17 Try adding this to Tins instructions, I have a 3 " steel disk, was a slitting saw but now its tool grinding helper. find a steel round like the slittting saw, the harder the better. rest your bit on the top of the disk, let the disk bear against the grinding belt of wheel, now when you bear down on the tool bit it will tend to carry the disk ...

获取价格

Help with grinding a step drill - Practical Machinist

2012/1/7 That is such an easy job to make an altered standard, perhaps a 3/8 or 1/2 drill with a .125 lead and 45* angle step you might get a bid for 12. A tool grinding shop will accommodate the angle to give you a proper 45" considering the helix of the cutter. Special Drill and Reamer in Michigan will give you a quote over the phone.

获取价格

Master The Art Of Grinding A Lathe Threading Tool ShunTool

2024/2/21 The first step in grinding a lathe threading tool is to select the appropriate grinding wheel. The grinding wheel should have the right grit and hardness to achieve the desired finish. For threading, a wheel with a fine grit and a hardness of around 60-70 HRC is commonly used. ... These tool bits typically have a slight side cutting edge ...

获取价格

sbm what are the steps in grinding toolbit.md

Write better code with AI Code review. Manage code changes

获取价格

Grinding Your Own Lathe Tools - VCSHobbies

Grinding Side 3 of the Tool FIGURE 9--Grinding the "Hook" into side 3. Use the skill you have developed grinding the second side now. Set the blank on the support with the 10° (side 1) up. The tool has to be brought up to the grinding wheel with a

获取价格

A Step-By-Step Guide To Creating A Diy Jig For Grinding Drills

2024/2/9 Step 4: Mount the Drill Bit. Place the drill bit into the jig with the cutting edge against the steel rod. Orient the drill bit at the desired grinding angle, aligning the marked angle with the angle formed by the drill bit and the rod. Tighten a clamp or bench vice to hold the jig and drill bit securely. Step 5: Begin Grinding

获取价格

Custom Step Drill - son-Campbell - One Tool, Two Jobs

Portland. 12820 S.E. Hwy 212 Clackamas, OR 97015 Phone: (800) 922-1263 Fax: (503) 212-5354 info@aronson-campbell

获取价格

sbm what are the steps in grinding toolbit.md

Write better code with AI Code review. Manage code changes

获取价格

Grinding Your Own Lathe Tools - VCSHobbies

Grinding Side 3 of the Tool FIGURE 9--Grinding the "Hook" into side 3. Use the skill you have developed grinding the second side now. Set the blank on the support with the 10° (side 1) up. The tool has to be brought up to the grinding wheel with a

获取价格

A Step-By-Step Guide To Creating A Diy Jig For Grinding Drills

2024/2/9 Step 4: Mount the Drill Bit. Place the drill bit into the jig with the cutting edge against the steel rod. Orient the drill bit at the desired grinding angle, aligning the marked angle with the angle formed by the drill bit and the rod. Tighten a clamp or bench vice to hold the jig and drill bit securely. Step 5: Begin Grinding

获取价格

Custom Step Drill - son-Campbell - One Tool, Two Jobs

Portland. 12820 S.E. Hwy 212 Clackamas, OR 97015 Phone: (800) 922-1263 Fax: (503) 212-5354 info@aronson-campbell

获取价格

Grinding Your Own Lathe Tools - Sherline Products

blank on the tool rest and start grinding side 1. Grinding Wheel Tool Rest 10° FIGURE 4—Grinding Side 1. Top of Tool (NOTE: Because of 7° angle on tool rest, side of tool is actually cut first.) 1/4" -3/16" FIGURE 5—Properly ground side 1. Move the blank back and forth across the face of the wheel

获取价格

steps in grinding a tool bit - kooks.co

steps in grinding tool bits - Newest Crusher, Grinding ... Grinding Your Own Lathe Tools - The Sherline Lathe, Milling ... Grinding lathe tools is easy, ... 14B, a home shop method of achieving the same finished shape in two steps with a tool that can be ground on a bench grinder.

获取价格

Grinding HSS Tool Bit - YouTube

观看视频36:522020/10/25 This video tackles how to grind the different shapes of tool bit.

获取价格

Guidelines for Boring Tool Grinding - The Home Machinist!

2003/4/17 I see a fair number of articles on grinding lathe tools for OD cutting but nothing for a boring bit. I'm planning to use a 3/4" bar with 5/16 HSS bit and would like to cut to a flat bottom so am going to use the 45 degree mount. See picture. Material is steel and ID will be a bit greater that 2 3/4". These will be fine cuts looking for precision.

获取价格

How To Grind A Hss Turning Tool The Hobby-Machinist

2016/11/30 The End Now we will grind the end face of the tool. The angle it forms relative to the side edge is called the end cutting edge angle and the clearance angle under this end edge is called the end relief angle, which is set by the angle of the tool rest. For most tools I recommend that the end relief angle be kept the same as the side relief angle; in this case, 15°.

获取价格

Metal Grinding Tools: The Complete Guide - Red Label Abrasives

Quick Summary Metal grinding is a crucial process in various industries, using abrasive wheels or belts for tasks like deburring and precision finishing. For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt grinders, bench grinders, die grinders, and surface grinders, as

获取价格

How to Sharpen Metal Lathe Tools Like a Pro: Tips and Tricks

2023/9/22 In this process, the top surface of the tool is re-shaped and honed to create a sharper edge. The first step is to examine the tool and determine the angle at which it needs to be sharpened. Once this has been determined, the tool is placed on a grinding wheel, and the top face is ground down to form a new and sharper edge.

获取价格

The Ultimate Guide to Lathe Bit Grinding for Swiss CNC Machining

2024/1/19 Step Description; Step 1: Set up the grinding equipment, ensuring proper safety measures are in place. Step 2: Secure the high-speed steel lathe tool bit in the grinding equipment, ensuring stability.

获取价格

how to grind HSS tool bit to 1/8" radius accurately

It's aluminum, 1 part. Drill a piece of steel for a "toolbit", Cut down to the quadrants, finish the rad with a file, add a bit of lead at the corners, and cut your one part. Don't even bother to harden it. I'd knock the corner of the part off a bit first so you're not doing a full pass. Or you could practice your grinding a bit, and do it out ...

获取价格تيتان عالية البوكسيت إثراء

والكسارة المستخدمة

مستعملة كتلة خرسانية ماكينة للبيع في الولايات المتحدة الأمريكية شركة زينيث

سعر كسارة تأثير التعدين المستخدمة في التعدين

مطاحن طحن للأوراق الجافة

سعر آلة طحن الفلفل الحار في الأردن

شركة المحاجر في السعودية جزيره العرب

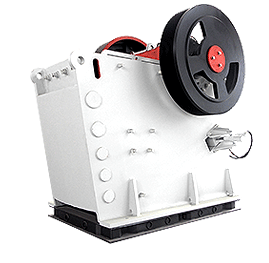

أسعار محطم استخدام الفك

كسارة فكية سلسلة Pex كسارة الصخور

مناجم ذهب للبيع السعودية

بيع كسارة مخروطية كوم

الحديد تعدين كسارة للبيع

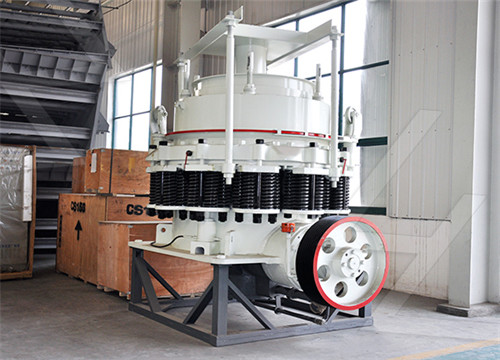

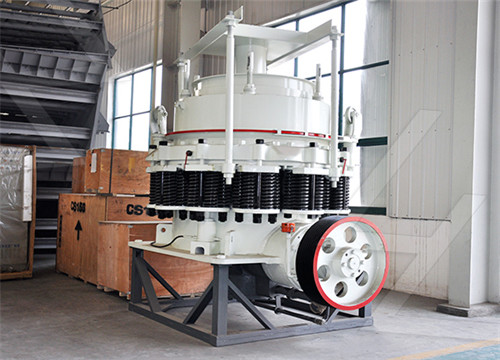

خدمة جيدة جنبا إلى جنب كسارة مخروط

ترشيح الهاليد في استعادة الذهب

صخرة تهتز الشاشة المملكة المتحدة

مطحنة سرعة المخفض لساليل

النقلات من وزارت الصناعة الى وزارت الكهرباء

سعر آلة تكسير الحجر جنوب أفريقيا

لوحة مقابل مطحنة بيليه الدوارة

معالجة مرشح السيراميك خام الذهب

فيديو كسارة الخرسانة المدمجة

aplikasi mata air dalam batu crusher

التحويل من ميل الى كيلو متر

دليل آلة التعويم المختبري موديل دنفر d 12

صنع الحلي النحاس

كسارة فكية ذات كفاءة عالية

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20