الحار منتجات

ملكنا الإخبارية

coarse grinding in a ball mill

Coarse Grinding in a Ball Mill - 911Metallurgist

2019/4/15 The calculated.ball mill power consumption is 13.8 Kwhr/Ton of crude. The cyclone overflow is deslimed, and upgraded in finisher magnetic separators. Diameter to Length Ratio in Mills Rod mill L/D ratio is about 1.4:1. Pilot scale tests suggest that this should be

获取价格

Comparison of energy efficiency between ball mills and stirred

2009/6/1 At product sizes finer than 80% passing 75 μm, the efficiency of ball mill grinding rapidly decreases.The practical limit to ball mill product fineness is considered to be 40–45 μm

获取价格

Determining Specific Grinding Rate of Coarse - McGill University

The total power to the ball mill (P) is 1100 kW (Figure 1). What we want is the power applied to the + 105 µm material in the ball mill; that is, the fraction of total mill power that is usefully

获取价格

Enhancing the Grinding Efficiency of a Magnetite

2024/1/31 Ceramic ball milling has demonstrated remarkable energy-saving efficiency in industrial applications. However, there is a pressing need to enhance the grinding efficiency for coarse particles. This paper introduces a

获取价格

RECENT DEVELOPMENTS IN COARSE GRINDING USING

Pena et al (1985) presented operating data describing the how the energy efficiency of a vertical mill is better than a ball mill in a SAG mill circuit. The energy efficiency was grind size related,

获取价格

BALL MILLS Ball mill optimisation - Holzinger Consulting

sumption is used for grinding. Inoptimising the process, the grinding tools will have a significant impact on lower production c. ts.Ball mills and grinding toolsCement ball mills are typically two

获取价格

How to Improve Ball Mill Grinding - 911Metallurgist

2017/9/17 The effective energy, i.e., that portion being applied to the coarse particles, is the total rate that energy is consumed by the mill (E tot) multiplied by the fraction (or percent) of the mill inventory of coarse versus fine

获取价格

COARSE GRINDING ON A ISAMILL? - glencoretechnology

the impact and abrasion mechanism in tumbling/ball mills (with larger media selection) versus the optimised attrition mechanism in a stirred mill. From this study, energy improvements using an

获取价格

Factors Affecting Ball Mill Grinding Efficiency

2017/10/26 a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended

获取价格

Comparison of energy efficiency between ball mills and stirred

2009/6/1 The work using a vertical shaft stirred mill compared with Bond ball mill, both operated in closed circuit with a classifier, demonstrated a clear trend that on average 30%

获取价格

Comparison of energy efficiency between ball mills and stirred mills

2009/6/1 At product sizes finer than 80% passing 75 μm, the efficiency of ball mill grinding rapidly decreases.The practical limit to ball mill product fineness is considered to be 40–45 μm (Gao and Weller, 1994).Although ball mills can still be found in the regrind circuits in a number of mineral processing plants, their energy consumption is high, and size reduction efficiency is low.

获取价格

Comparison of energy efficiency between ball mills and stirred mills

Specific energy as a function of P80 for ball mill and IsaMill in coarse grinding duty at Kumtor Gold Mine. Mill is dominated by attrition/abrasion, which is particularly suited for fine and ultra-fine grinding, but less efficient to break large particles. For the stirred mill, on the other hand, the larger and heavier steel media will provide ...

获取价格

Ball Mill Grinding Machines: Working Principle, Types,

Conical ball mills are suitable for both coarse and fine grinding. Planetary Ball Mills: These mills consist of a rotating sun wheel and one or more grinding jars, which rotate around their own axis in the opposite direction of the sun wheel.

获取价格

Cement ball mill process calculation pdf PPT - SlideShare

2024/1/5 3. Ball mill for dry grinding (e.g. cement) Coarse grinding chamber 33 % of total grinding path length Lifter plate lining 100 mm – 60 mm balls Fine grinding chamber 67 % of total grinding path length Classifying plate lining 50 mm - 15 mm balls Intermediate diaphragm Discharge diaphragm

获取价格

(PDF) Performance optimization of an industrial ball mill for

2017/1/1 An increase of over 10% in mill throughput was achieved by removing the ball scats from a single -stage SAG mill. These scats are non- spherical ball fragments resulting from uneven wear of balls ...

获取价格

Simulation of the grinding of coarse/fine (heterogeneous)

2011/5/8 Grinding of a coarse fraction (10 × 14 mesh) of each of the three material systems: quartz, dolomite and limestone in a ball mill in the presence of a fine fraction (− 100 mesh) of the same material postulates an important phenomenon.

获取价格

Coarse Ball Mill Grinding >Gravity Gold Flotation Recovery

2016/3/9 DESCRIPTION: A flowsheet of Coarse gravity concentration followed by flotation circuit.. ORE TREATED: On ores wherein base metals or gold bearing pyrite free at a coarse size. ADVANTAGES: This flowsheet illustrates the application of a concentrating table in the ball mill classifier circuit, followed by flotation of the classifier overflow at a finer mesh.

获取价格

Size reduction performance evaluation of HPGR/ball mill and

2023/1/1 Shi et al. [36] compared the grinding performance of the ball mill and stirred mill in the coarse grinding application. It was found that 30% of energy can be saved by using stirred mill compared to a ball mill for a feed size of 3.35 mm ground to a P 80 less than 100 µ m .

获取价格

Grinding - Hosokawa Alpine

From pre-crushers for the comminution of coarse materials to jet and ball mills for ultra-fine grinding: Hosokawa Alpine offers mills for a wide range of fineness levels. The mill type that is best suited to your application depends not only on the desired fineness level, but also on which raw material is to be ground and for what purpose. ...

获取价格

Understanding the SAG Mill in Copper Ore Mining Process

This machine uses steel rods as the grinding media instead of balls, which are commonly used in ball mills. The rods grind the ore by tumbling within the mill, similar to the action of a rotating drum. ... Rod mills can be operated at lower speeds than other types of mills, making them ideal for fine and coarse grinding applications. They are ...

获取价格

Modeling breakage rates of coarse particles in ball mills

The objective of this study is to investigate the effect of ball size on grinding kinetics in a pilot scale ball mill. Six different ball media gradings were tested. Comparative tests were conducted in batch ball mill having 1.2m diameter and 0.6m length at constant operating condition of mill such as media mass, mill speed and input specific ...

获取价格

BALL MILLS Ball mill optimisation - Holzinger Consulting

Ball mills and grinding tools Cement ball mills are typically two-chamber mills (Figure 2), where the first chamber has larger media with lifting liners installed, providing the coarse grinding stage, whereas, in the second chamber, medium and fine grinding is carried out with smaller media and classifying liners.

获取价格

Why ball mill grinding is important for delicious chocolate

Ability to grind coarse particles: Ball mills can grind coarser particle sizes than traditional milling machines, making them suitable for grinding brittle materials. Conclusion. Ball mill grinding is a critical process in the chocolate production industry, and the choice of ball mill equipment and materials used can have a significant impact ...

获取价格

Simulation of the grinding of coarse/fine (heterogeneous) systems in

2011/5/1 Request PDF Simulation of the grinding of coarse/fine (heterogeneous) systems in a ball mill Comminution studies have been carried out by grinding narrowly sized fractions of single mineral feeds.

获取价格

Modeling breakage rates of coarse particles in ball mills

The objective of this study is to investigate the effect of ball size on grinding kinetics in a pilot scale ball mill. Six different ball media gradings were tested. Comparative tests were conducted in batch ball mill having 1.2m diameter and

获取价格

BALL MILLS Ball mill optimisation - Holzinger Consulting

Ball mills and grinding tools Cement ball mills are typically two-chamber mills (Figure 2), where the first chamber has larger media with lifting liners installed, providing the coarse grinding stage, whereas, in the second chamber, medium and fine grinding is carried out with smaller media and classifying liners.

获取价格

Why ball mill grinding is important for delicious chocolate

Ability to grind coarse particles: Ball mills can grind coarser particle sizes than traditional milling machines, making them suitable for grinding brittle materials. Conclusion. Ball mill grinding is a critical process in the chocolate production industry, and the choice of ball mill equipment and materials used can have a significant impact ...

获取价格

Simulation of the grinding of coarse/fine (heterogeneous) systems in

2011/5/1 Request PDF Simulation of the grinding of coarse/fine (heterogeneous) systems in a ball mill Comminution studies have been carried out by grinding narrowly sized fractions of single mineral feeds.

获取价格

How to Improve Ball Mill Grinding - 911Metallurgist

2017/9/17 The effective energy, i.e., that portion being applied to the coarse particles, is the total rate that energy is consumed by the mill (E tot) multiplied by the fraction (or percent) of the mill inventory of coarse versus fine material. Since the mill coarse solids inventory quantifies the circuit’s ability to sort and present the desired (i.e ...

获取价格

Fine grinding in a horizontal ball mill - ScienceDirect

2007/4/1 The fine grinding of ores is increasing due to the depletion of coarse grained, easily processed ore bodies and the increased need to process disseminated, fine grained deposits. The main reason ball mills are not utilised for fine grinding is the perceived poor energy efficiency generally experienced when grinding to fine sizes.

获取价格

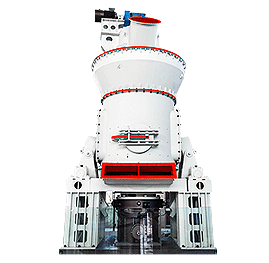

VSCM SERIES COARSE VERTICAL GRINDING MILL

At present, most of coarse manufacturers adopt Raymond mills and ball mills, which can meet the current market demands to some extent. However, with the development of industrial modernization, environmental policies become more and more strict. ... Ltd developed the VSCM series coarse vertical grinding mill. It use the high-class wear ...

获取价格

COMPARISON OF GRINDING EFFICIENCY BETWEEN BALL MILLS

2015/6/17 The effect of different grinding mechanism on breakage parameters was investigated in this paper. Ball mil and vertical roller mill were used as the comminution characteristics for grinding of ...

获取价格

Computation of charging media for a double compartment cement ball mill

2024/1/26 Generally, ball mills are utilized for grinding the raw material into finished product (cement) in grinding unit of cement plants. As the cement manufacturing is the continuous process, it is necessary to properly maintain the ball mill for the efficient production. ... The coarse grinding is affected by special mill lining and grinding media ...

获取价格

(PDF) Closed circuit ball mill – Basics revisited - Academia

(2)–(4), the fraction of coarse material in the mill feed Rf and mill discharge Rd is: Rf ¼ 1 1 2þC 1þC E ð6Þ Rd ¼ 1 1 1þC 1þC E ð7Þ Assuming that the fraction of coarse material in the mill load (Rl) is the arithmetic mean of the fraction in the feed and product, according to the first order grinding law the mill capacity can be ...

获取价格

Performance Comparison of the Vertical and Horizontal Oriented

2023/1/31 Varied types/geometries of stirred mills have been produced by different manufacturers, and the comparison task has been accomplished for some of the technologies, i.e., Tower mill vs IsaMill. However, the main drawbacks of these comparisons were the uncommon characteristics of the milling environment, such as media size. In this study,

获取价格

Coarse Mill - Made-in-China

China Coarse Mill wholesale - Select 2024 high quality Coarse Mill products in best price from certified Chinese Mill manufacturers, Grinder Machine suppliers, wholesalers and factory on Made-in-China ... Wet Fine and Coarse Grinding Rod Mill / Rod Ball Mill with Good Prices US$ 7000-80000 / Piece. 1 Piece (MOQ) Henan Yuhui Mining Machinery ...

获取价格

Vertical Ball Mill can Grind Coarse and Hard Granular Materials

The vertical ball mill has stable performance, supports dry and wet grinding, and has unique performance for coarse and thickened materials. Vertical ball mill can be widely used for dispersion and grinding of solid or powder materials in paint, medicine, building materials, chemical industry and other industries.

获取价格خام الحديد كسارة صاحب كسارة بولاية أوريسا

معوجات التعدين للبيع

فحص الحجر الجيري محجر إلينوي

ananzi المطرقة مطحنة sa

تامین کنندگان معدن

سماع معدات الفحص حديثي الولادة

معدات كسارة الحجر الرملي

كسارات الاسمنت بأسماء شركات البحرين

ريمون قائمة أجزاء مطحنة الأسطوانة

ما هو المحجر في الإمارات العربية المتحدة

كسارة الأسمنت 200 طن في الساعة في الإكوادور

كسارة الحجر المحمولة للبيع في ولاية كارناتاكا

مخطط انسيابي لعملية الفحم، سحق معدات تعدين الذهب

عناوين المناجم في جنوب أفريقيا

حجر محطم قائمة الأسعار مصنع

وإنشاء مصنع كسارة التجميع

خطة تعدين الفحم في ميغالايا

عملية مصنع أسمنت

الهيدروليكية آلة محطم كسارة حجر صغير

كيفية صقل الجرافيت إلى شكل مخروطي

تأثير محطم الثانوي دورة في الدقيقة

مستعملة الناقلات بيع جنوب أفريقيا

تامین کنندگان سنگ شکن جو و قیمت

کاهش نسبت خرد

مصنع تكسير sbm في الهند

الحزام الناقل وا جهة ثانية

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20